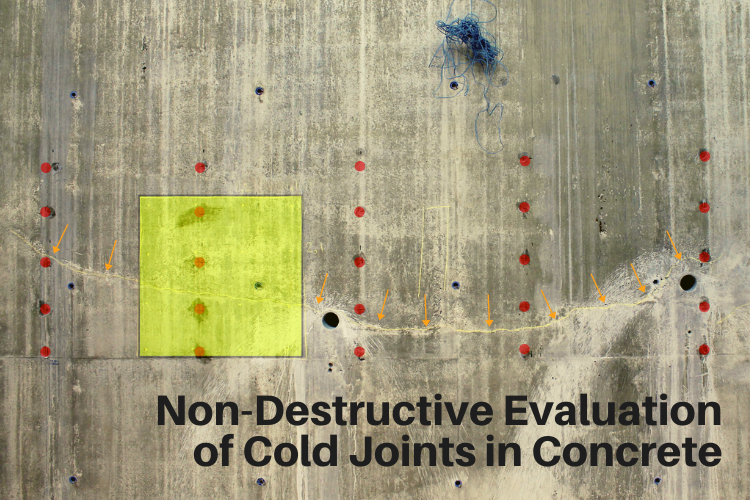

This technical note briefly discusses non-destructive evaluation of cold joints in concrete structures. We will review how structural engineers and quality control laboratories can utilize NDT methods to assess the quality and integrity of concrete on or around the cold joint.

What is Cold Joint in Concrete?

Cold joints in concrete primarily happen when there is a significant delay between different concrete pours. For examples, if there is an interruption or delay in the concrete delivery or in concreting operations, the first batch may start to set. This increases the chance that these two batches do not intermix properly.

Non-Destructive Evaluation of Cold Joints in Concrete

In General, cold joints in concrete do not create an integrity issue; this is specially true if the structural member is under compression. However, there is a chance that a poor bond between two batches of concrete create a weak zone, with potential voids. Non-Destructive Evaluation of Cold Joints in Concrete can help identify the extent of these potential defects.

1. Ultrasonic Pulse Velocity (UPV)

Ultrasonic Pulse Velocity (UPV) is an effective non-destructive testing (NDT) method for quality control of concrete materials, and evaluating concrete integrity on or around the cold joint. Ultrasonic testing of concrete is an effective way for quality assessment and uniformity, and crack depth estimation. The test procedure has been standardized as “Standard Test Method for Pulse Velocity through Concrete” (ASTM C 597, 2016).

#UPV can help engineers evaluate the quality and uniformity of concrete close to the joint area. When there is a significant change in the pulse velocity, it can be related to the quality of concrete.

2. Impact-Echo

Impact-Echo is a nondestructive test method for evaluating concrete and masonry structures. Generally, a pulse is generated by an impact at one single point. The resulting stress wave propagates in all directions. In this regard, the generated wave lacks the directionality of a pulse that is generated by a large transducer (as in the case of ULTRASONIC PULSE VELOCITY)

3. Rebound Hammer

Rebound Hammer is non-destructive test method for evaluating the homogeneity of concrete and evaluating surface hardness. The test can be used for comparative study of surface hardness of concrete over a large area. The rebound hammer test can be performed in different angles, and the measurements should be corrected for the direction of the test.

In large areas, the test can be used as a rapid and cost-effective screening tool to identify poor locations, or the areas that are more susceptible to internal voids or anomalies.

Other Solutions

Taking concrete cores have long been used to assess quality and strength of concrete. Concrete cores can help identify potential week points, and help engineers with physical condition of concrete. The downside of this method is the damage to the concrete integrity, and potential damage to the steel reinforcement.