Introduction

Bridges are among the most important infrastructure facilities. So far, the inspection and testing of bridge structures have largely been limited to visual inspection, chain dragging, extracting cores, and in some cases, half-cell corrosion potential mapping. Lots of interesting research have been done by researchers around the globe to bring more innovative NDT solutions to this sector. The following article focuses on the applications of most widely used non-destructive testing for detailed bridge condition survey.

Nondestructive Testing and Evaluation (NDT-E)

The Second Strategic Highway Research Program (SHRP 2) has identified various NDT-E techniques for condition assessment of bridge decks. The report ranks these methods based on their effectiveness in the detection and characterization of four major deterioration types:

- Delamination

- Concrete degradation

- Corrosion of Rebar

- Vertical cracking

Bridge Condition Assessment

Most bridge deck condition survey projects aim to better understand the condition of deck through a set of intrusive and non-intrusive tests. The goal is to identify the location of potential anomalies, identify their extent, and severity, and prioritize the maintenance needs. Asset owners and their consultants often look for the following information

- Visual Condition of Concrete

- Locate Delamination

- Estimate the Thickness of Concrete Deck

- Estimate Cover thickness

- Concrete Strength

- Concrete Chloride Content

- Concrete Penetrability (Chloride)

- Inspect the condition of steel rebar

- Air content

1- Visual Survey and Sounding

Visual Surveys, and Sounding through chain dragging are still one of the most popular tests. The main reason behind their wide use is their simplicity and cost. No special equipment is needed. However, the application of the method for detecting delaminated areas can be limited when the background noise (from the traffic) is too high.

Drones have changed the landscape of visual survey for bridge structures. Drones can help engineers collect key information of structural deficiencies, and eliminate the need for rope access inspection, or Bridgemaster (Bridge Inspection Trucks)

The most recent development in this area is the use of advanced acoustic sensors to collect the hollow sound at traffic speed. The main advantage of these methods is that they do not need special traffic control or lane closure.

Thickness of Concrete Deck

Extracting through the thickness concrete core (full depth) is used to evaluate the total thickness of the concrete deck. While this is important in evaluating the dead load of the bridge deck, the procedure provide limited information. For bridge inspections that Bridge Master is not used, access to the underneath of the deck is often limited and extracting full depth core is challenging.

As an alternative, Non-Destructive Test method such as Ultrasonic Pulse Echo can be used to evaluate the thickness of the bridge deck. While the accuracy of the test method in areas with dense rebar spacing is limited, the results from the Mid-Span are accurate. Impact-Echo is another great NDT tool for evaluating the thickness of concrete decks.

Concrete Cover Thickness

Evaluating concrete cover thickness using Non-destructive test method is already a market standard. The test results can be verified at the location of concrete sawing. Most modern Ground Penetrating Radar devices can provide a good estimate of the rebar depth. Assuming that the rebar depth is not going to change over time (unless there is a major intervention), application of NDT can significantly reduce the number and areas that need to be uncovered for this purpose.

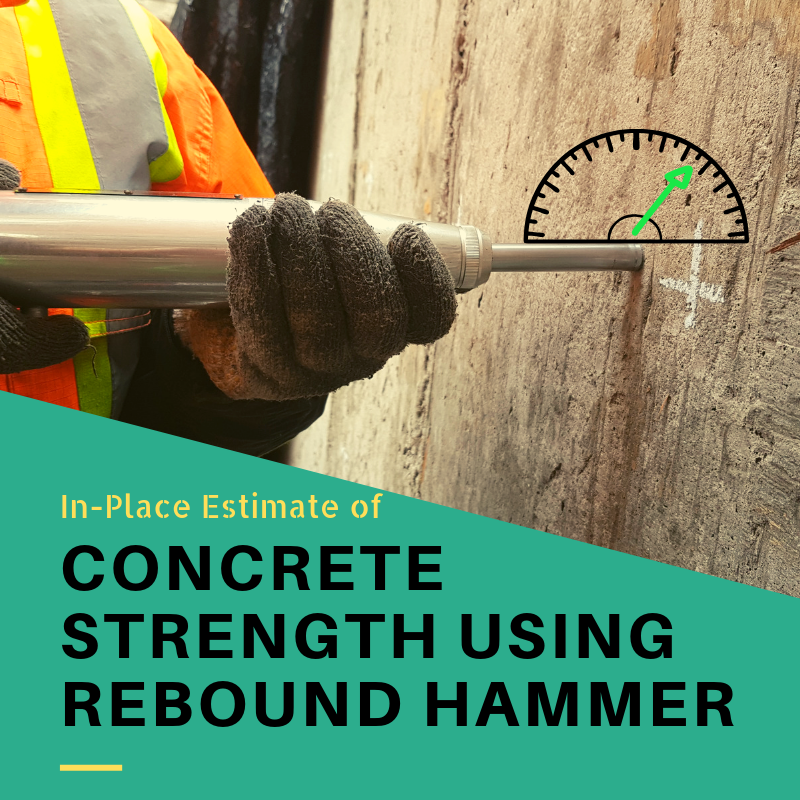

Concrete Strength

Concrete cores are often extracted to study the mechanical and durability properties of concrete. Cores can be tested to provide information about the compressive strength. They can also be tested for chloride content and air content. While the total number of concrete cores can be quite significant for larger bridge decks, a few of these cores are further studied for strength or chloride content. Some of the most common challenges of concrete coring is summarized here.

When it comes to concrete strength, combined NDT methods can be used. A combination of rebound hammer and ultrasonic pulse velocity can help engineers estimate the strength of concrete. The method can help reduce the number of cores that are needed for this purpose.

Concrete Chloride Content

Chloride and air content are the only tests that cannot be determined through NDT at this time; However, the use of surface electrical resistivity can enhance our understanding of the bridge deck condition.

Corrosion Inspection and Monitoring

Corrosion inspection in concrete bridge deck is mainly done through Half-Cell Corrosion Potential Survey (ASTM C 876). Half-cell test provides valuable information about the likelihood of corrosion activity in concrete bridge decks. However, the results can be inconclusive for epoxy coated rebar, decks with asphalt overlays, and decks with waterproofing membrane.

Another important test can be corrosion rate monitoring. This is very useful in evaluating the service life of the bridge structure. Surface electrical resistivity can also help engineers in getting useful information about the concrete quality.

Concluding Remarks

Most of the tests that are currently included in most bridge deck condition surveys can be replaced or complemented with commercially available NDT solutions in the market. Most NDT solutions can deliver results with same or higher accuracy, while reducing the inspection timeline, intervention in the structure, and reducing the damage to critical elements. Application of different Non-destructive testing for detailed bridge condition survey has been studies by many researchers and engineers. With the recent advancements in sensor technology, and wireless communication, Structural Health Monitoring (SHM) solutions are becoming more cost-effective for general applications, and can help engineers and owners in near future.

Common Defects in Bridge Structures | FPrimeC Solutions

[…] NDT for Detailed Bridge Deck Condition Survey […]

Afton Jackson

I like this informative article about bridge surveying. It is new to me that there are devices that measure the corrosion of structures. If ever, these bridge monitoring sensors can detect if a certain part of the structure needs replacement.

Randy Chorvack

It's interesting that they'd ask for air content to be surveyed when they're building a bridge. Why do they need to know what's in the air when they don't really have anything to do with it? My cousin is in construction so maybe he knows the answer to that. I'll have to ask him next time I see him.

Bimal

This is nice blog. Thanks admin for share this post. This is helpful for Bridge Engineers. I am also working in this field as bridge inspector. This is helpful for "Bridge Inspection and Maintenance and NDT Test In Bridge"