Scope

FPrimeC was hired by Go West Construction Corp. to perform comprehensive inspection at Sopa Square Parkade in Kelowna, BC. More than 7000 sq.m of concrete slab on grade was inspected using FPrimeC’s innovative testing solutions.

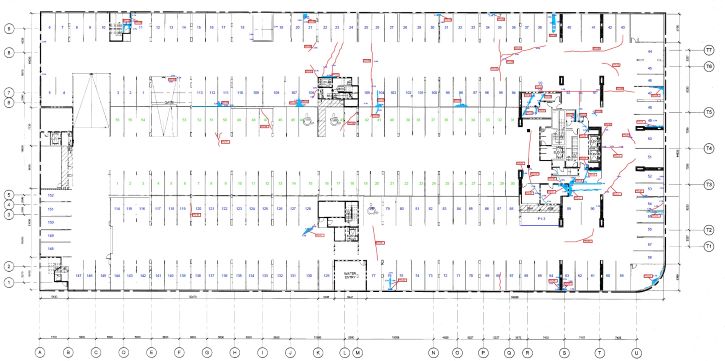

The main objective of the project was to assess the existing cracks over the slab-on-grade in the Parkade (Read more: NDT for Parking Garage Inspection), identify the source of moisture ingress into the building envelope, and identify major maintenance needs.

Solutions

1- Comprehensive Visual Inspection

The parkade SOG was visually inspected using optical cameras to identify major cracks with active moisture ingress. Where applicable, physical measurements (dimensions, length, area) were performed using a measuring tape and laser measurer to determine the approximate locations of defects.

2- Non-Destructive Testing of Concrete Crack Depth

A special configuration of Ultrasonic Pulse Velocity (UPV) method is used for estimating the depth of surface cracks over concrete elements. For this application, indirect configuration is generally used: Both transmitter and receiver were place over the surface of the concrete slab (bottom surface). Each of the two transducers (transmitter and receiver) were placed on one side of the crack with identical distance from the crack line.

3- Non-Destructive Evaluation of Moisture Ingress

Two different non-destructive testing methods were used to assess for the moisture content over the test areas: Infrared Thermography (IRT) camera and Moisture meter. Infrared Thermography (IRT) is an imaging technique that uses long infrared electromagnetic spectrum to detect radiations emitted from different elements and objects. The range of spectrum for IRT camera varies between 9,000 to 14,000 nanometers for detecting thermal radiation. The IRT can differentiate between elements and objects based on the thermal electromagnetic radiations.

Concrete Moisture meter is a non-destructive method for measuring moisture content instantly in concrete slabs as per ASTM F2659, “Standard Guide for Preliminary Evaluation of Comparative Moisture Condition of Concrete, Gypsum Cement and Other Floor Slabs and Screeds Using a Non-Destructive Electronic Moisture Meter”. This method is used to obtain the comparative moisture condition within the upper 1.0 in. (25.4 mm) stratum in concrete. The Concrete Moisture meter detects and evaluates the moisture conditions within the slab by measuring the electrical impedance of the concrete. A low frequency electric signal is transmitted into the material into the test area using direct contact between concrete and device electrodes. The strength of this electric signal directly correlated to the near surface moisture content of the concrete.