Surface Electrical Resistivity of Concrete

Surface Electrical Resistivity of Concrete testing is a non-destructive method used to evaluate the ability of concrete to resist the movement of electrical current and ions.

Because ionic transport governs moisture movement and chloride ingress, surface resistivity is widely used as an indicator of concrete durability and corrosion risk in reinforced concrete structures.

The test is commonly applied to bridges, parking structures, marine and industrial facilities, foundations, and slabs, both in new construction and existing structures.

The Concept

Electrical resistivity is defined as the opposition of a material to the flow of electrical current. In concrete, current is primarily conducted through the pore solution, making resistivity strongly influenced by:

Moisture content

Pore structure and connectivity

Chloride concentration

Cementitious materials and mix design

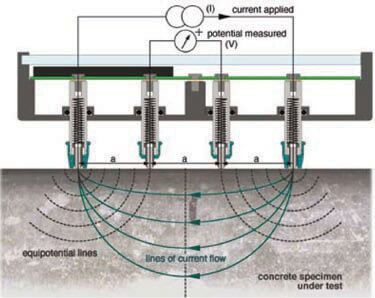

Surface resistivity is typically measured using a four-point Wenner probe, which applies an alternating current through the outer probes and measures the resulting voltage between the inner probes.

ρ=2πa V/I

Where:

ρ = surface resistivity (kΩ·cm)

a = probe spacing

V= measured voltage

I= applied current

Applications

Surface electrical resistivity testing is commonly applied to:

Assess durability performance of concrete (materials and structures)

New construction quality control

Condition assessment and durability studies

Applicable Standards and Guidance

Surface electrical resistivity testing is governed by well-established standards:

AASHTO T 358 – Standard Method of Test for Surface Resistivity Indication of Concrete’s Ability to Resist Chloride Ion Penetration

ASTM C1876 – Standard Test Method for Bulk Electrical Resistivity or Bulk Conductivity of Concrete

Integration with Corrosion and Durability Assessment

Surface resistivity is most powerful when combined with:

Corrosion rate (LPR / galvanostatic pulse) testing

Chloride profiling and carbonation depth

Visual and structural condition surveys

Together, these methods support a holistic, data-driven approach to corrosion management and service life planning.

Please contact us for a free quotation and tell us more about your project