The Problem

FPrimeC Solutions was hired by a Shotcrete Contractor to verify the quality and integrity of shotcrete on or around a cold joint that was formed during the shotcrete construction. A repair program using crack injection had been proposed by a third-party contractor. The shotcrete contractor and engineer of record requested testing shotcrete wall in pumping station to assess the quality of shotcrete in the area of interest before and after repair.

Testing of Shotcrete Wall in Pumping Station

The area under investigation was a predominantly horizontal cold joint. Preliminary investigation by a third-party inspector showed sign of cracking in the shotcrete wall. The client requested a testing solution that could provide clear data on the quality and integrity of shotcrete in the affected area, before and after repair. In order to achieve this objective, FPrimeC designed a multi modal nondestructive testing program to assess the area. The test plan involved two key NDT methods:

1- Ultrasonic Pulse Echo Tomography (UPE)

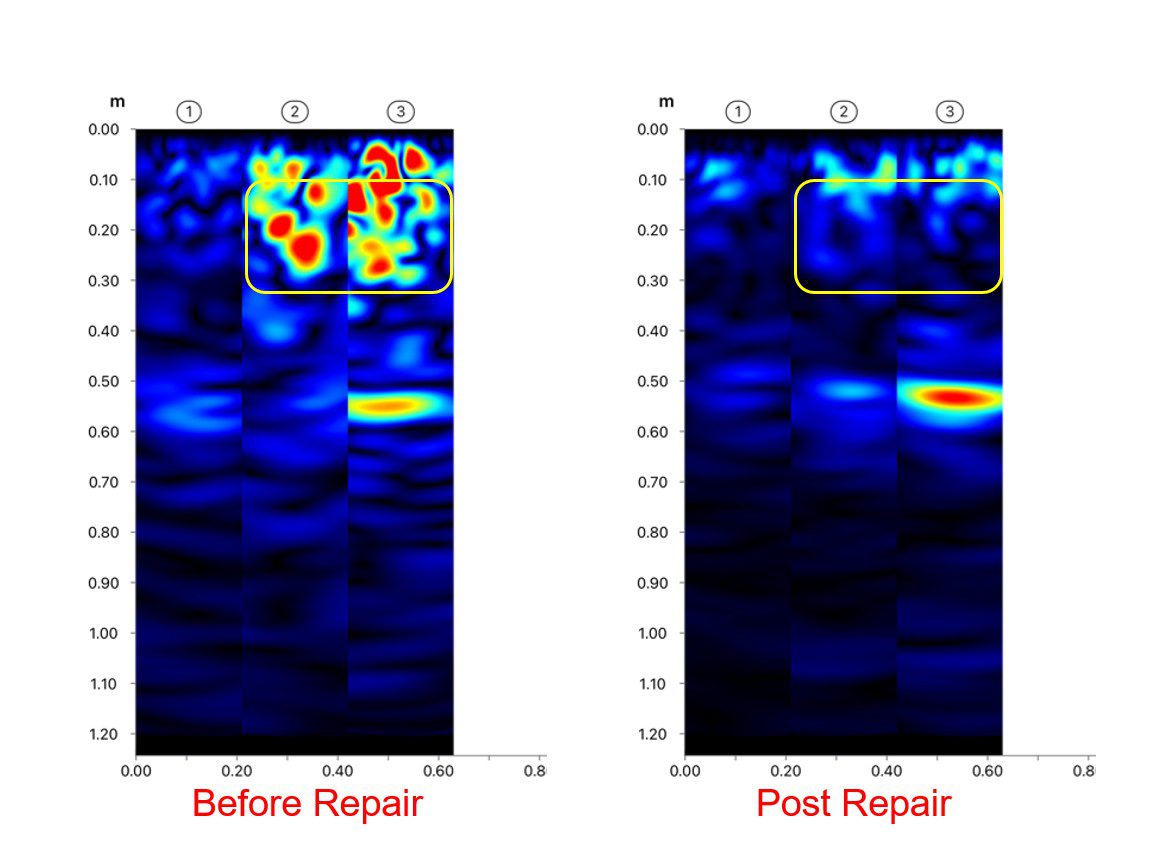

The main assessment protocol was the Ultrasonic Pulse Echo. The test area was divided into a horizontal and vertical grid of 100 mm x 100. The UPE scan was performed in Line Scan before and after the repair injection program. The general idea behind this testing solution was to see if the voids, and cracks are effectively filled by grout or not.

2. Ground Penetrating Radar (GPR)

The GPR test was only performed as a secondary practice, mainly to identify the location of steel rebar. This was done to minimize the risk of false-positive interpretations due to presence of steel reinforcement (especially in congested areas).

Assess Shotcrete Quality Before and After Repair

UPE proved to be an effective tool for testing shotcrete wall in pumping station, before and after repair (crack injection). The potential anomalies (reflections from likely voids and cracks) appear to have a lower intensity in the B-Scans. The method was used as a tool for minimal intrusive assessment for verification of quality. The approach helped parties keep core drilling to a minimum, and achieve higher confidence in certifying the quality of shotcrete wall without the need for removal. The approach also enabled FPrimeC to provide the client with percentage of areas with potential anomalies, and quantify the degree of improvement after repair.