Detect Voids under Concrete

FPrimeC was hired by a property management company to detect voids under concrete slab in a car dealership facility. A few locations in the service area exhibited sign of rocking and movement when subject to heavier vehicle load. Presence of voids and cavities under concrete floors and slab-on-grade (SOG) is a critical issue. Voids can negatively impact the structural performance of the slab under heavy machinery load, result in unplanned shut downs. Voids can also impact the normal operation in warehouses, industrial plants, and roads.

Various nondestructive solutions are available for detecting voids and cavities under slabs, and concrete floors (read more: NDT methods for Detecting Voids under Concrete). The selection of proper method comes down to a few factors, including:

- How big is the area

- The size of voids

- The location of voids (within concrete, under concrete, or within the soil layer)

- The type of concrete floor (plain concrete, reinforced concrete, or steel fibre reinforced concrete)

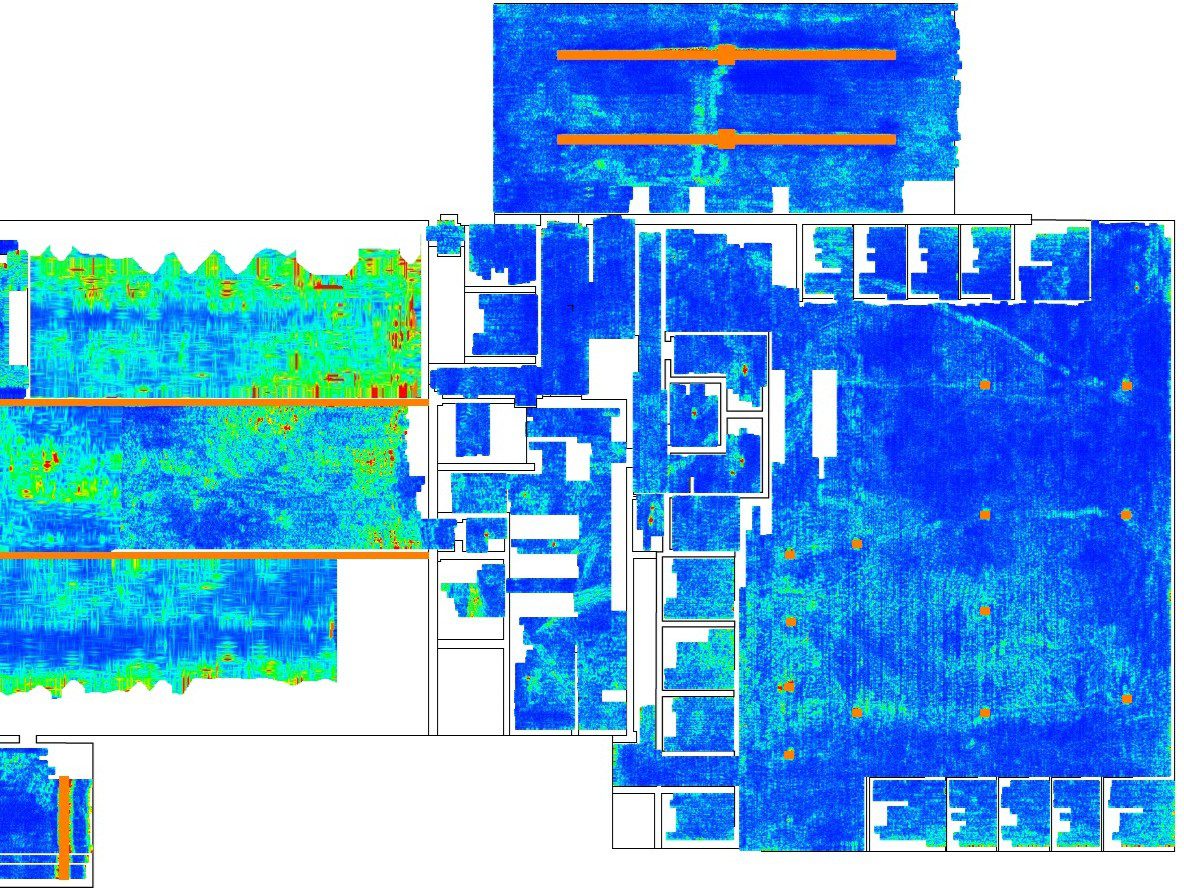

GPR Survey to Detect Voids under Concrete

FPrimeC conducted a multi modal NDT assessment to verify the location of potential voids within and underneath concrete slabs. Ground Penetrating Radar (GPR) was used for rapid screening of a large floor area across the showroom and the service area. The test area was break down into smaller area to avoid unnecessary interruption of the operation (sales and services), and to minimize the impact of trenches and other equipment in the scans. A multi-channel stepped frequency GPR was used to assess the location of potential voids. The GPR scans were collected in two orthogonal directions. The GPR scans were combined in the Geolitix platform to create slice views. The slice views were carefully examined to identify the location of potential voids at the interface of concrete and soil, and within the soil (possibility of sinkhole).

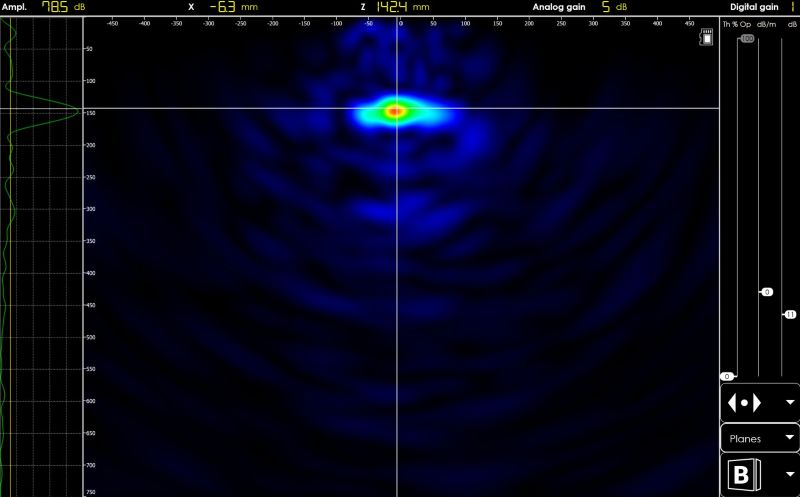

UPE Tomography to Detect Defects in Concrete Slab

Additional scanning was performed using Ultrasonic Pulse Echo to identify potential defects (delamination, honeycombing, major cracks) within the concrete floor. The UPE B-Scans were carefully examined by FPrimeC NDT engineers and technicians and all locations with potential sign of deficiency were marked.