Introduction

Modern transportation infrastructure is changing rapidly, and modernizing inspection practices for evolving transportation infrastructure plays a crucial role. With growing demands for durability, longer service life, and fewer maintenance needs, engineers and asset managers are embracing innovative construction materials and systems. Across North America and beyond, bridge and tunnel projects are increasingly using cable-stayed systems, ultra-high-performance concrete (UHPC), glass fiber-reinforced polymer (GFRP) reinforcement, and fiber-reinforced tunnel linings. While these materials bring important performance improvements, they also introduce challenges when it comes to inspection, testing, and quality assurance. Non-destructive testing and evaluation (NDT-E), along with structural health monitoring (SHM), are evolving to keep pace with these advances (Grosse et al., 2023). Traditional NDT techniques—designed primarily for steel-reinforced concrete—often fall short with new materials. This article explores how NDT-E practices must evolve to support modern bridge and tunnel infrastructure.

Current State of Practice

NDT-E is already proving its value in the condition assessment of transportation infrastructure. In particular, bridge industry has adapted NDT-E in various ways. Ground-penetrating radar (GPR), and infrared thermography have shown promising results in rapid screening of bridge decks, and Half-cell corrosion potential mapping is a standard test protocol in many bridge deck condition surveys. The Strategic Highway Research Program (SHRP2, 2013) have demonstrated how combining different NDT-E methods can significantly improve accuracy in bridge evaluations.

Despite this progress, NDT-E is not yet widely embedded into routine infrastructure inspection. Visual assessments—typically performed every two years—remain the default approach in many jurisdictions (i.e. Ontario Structure Inspection Mannal, 2008). Select NDT methods are requested only when problems are suspected (during inspections) or major rehabilitation is being considered.

Figure 1 – Half-Cell Corrosion Potential Mapping for Concrete Bridge Decks is a routine practice in bridge deck rehabilitation programs

Why Adoption Has Been Slow

It’s natural to ask: If NDT-E and SHM are so effective, why haven’t they become standard tools across the industry?

One way to understand the challenge is to compare the use of NDT in metals with its application in concrete. For steel structures – like pipelines, tanks, and pressure vessels – NDT techniques such as ultrasonic testing, radiography, and magnetic particle testing are widely used. These methods are supported by decades of research, detailed standards, and consistent workflows. The reason they work so well is that steel is a uniform, predictable material (being isotropic and homogenous).

Concrete, on the other hand, is a nonhomogeneous material. It’s composite and non-uniform nature, affected by how it was mixed (aggregates, paste), and placed, and changes over time due to shrinkage or chemical attack. Because of this variability, collecting reliable NDT-E measurements is generally challenging. Unlike steel, there are fewer universally accepted standards or guidelines for how to interpret those results. That uncertainty makes it harder for inspectors and engineers to confidently use NDT-E for decision-making. For example, Half-Cell Corrosion Potential Mapping, a market-standard practice for bridge deck survey, may produce different outcome when performed in different temperatures and moisture content (Gu, and Beaudoin, 1998).

Another hurdle is the level of expertise required. NDT-E for concrete calls for knowledge in materials science, instrumentation, signal processing, and structural behavior. Many inspection teams simply aren’t equipped with that range of skills, and hiring or training staff with that expertise takes time and resources.

A further issue is integration—or the lack of it. Most asset management systems are designed around simple inspection ratings (qualitative rating mostly based on visual condition). They’re not built on incorporating sensor data, NDT-E results, and analysis (quantitative assessment). consequently, valuable information from NDT-E surveys may end up disconnected from the tools that engineers rely on to make maintenance and repair decisions.

New Materials, New Challenges

The move toward advanced materials in bridges and tunnels presents a new layer of complexity. GFRP bars, for instance, provide superior resistance to corrosion and have a high strength-to-weight ratio. But since they’re non-metallic, they can’t be easily be detected using traditional electromagnetic tools like GPR or cover meters. The non-metallic nature of these bars, along with similar dielectric properties to concrete results in a less significant contrast in GPR scans. This may result in complexities in future interventions, increasing the chance of damage to rebar during drilling and cutting concrete.

Figure 2 – GFRP in bridge pier cap rehabilitation (photo courtesy of MST-Rebar, used with permission)

UHPC is another material gaining traction for its strength and durability. However, it’s denser than regular concrete, which makes it difficult to evaluate with tools like rebound hammers or standard ultrasonic tests. Fiber-reinforced concrete (FRC), common in tunnel linings and sprayed concrete applications, improves the structural and durability performance of these elements; however, the presence of steel fibers interferes with signal readings in many conventional NDT tools. For example, GPR is generally ineffective in evaluation of FRC elements.

Segmental and modular construction techniques—especially in tunnels and bridges—create additional quality control challenges. Evaluating the quality of grouting in post-tensioning ducts holding the segments need to be verified using techniques beyond the capabilities of visual inspection. Similarly, cable-stayed bridges and post-tensioned systems require specialized methods to monitor stress conditions and detect potential issues in anchor zones or tendons during the service life of the asset.

Evolving NDT-E for Modern Infrastructure

To respond to these challenges, NDT-E methods must become more targeted and material-specific. For instance, GPR and ultrasonic pulse-echo have shown promise in detecting GFRP bars in controlled environments (Malla et al, 2023), but their performance on real construction sites remains inconsistent. Further research on technology and data interpretation is required to provide reliable solutions.

Figure 3 – Conventional GPR scan of GFRP reinforced Concrete Slab in Laboratory Environment

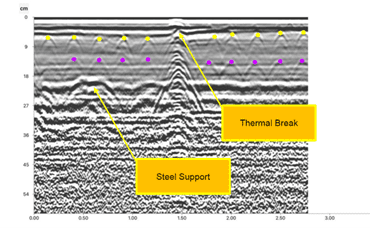

In tunnel linings made from fiber-reinforced precast segments, techniques like pulse-echo tomography and impact-echo are effective in locating voids and verifying grout condition behind the lining. UHPC components, due to their low porosity, may require surface wave analysis, acoustic imaging, or embedded sensors for reliable evaluation.

For structures with complex stress profiles, such as cable-stayed systems, methods like guided wave ultrasonics, vibration monitoring, and acoustic sensing appear to be the useful in detecting internal issues early—before they become critical.

NDT-E Across the Lifecycle

NDT-E adds value throughout an infrastructure asset’s life—not just during maintenance. During construction, these tools can be used as part of the quality control and quality assurance programs, and help verify shotcrete thickness, ensure joint grouting, and detect early defects like honeycombing in UHPC. That helps ensure the project meets its quality benchmarks before it even opens to the public.

Figure 4 – Ultrasonic Pulse Echo scanning of post-tensioning ducts as part of QC/QA of post-tensioned girders

Once in service, periodic NDT-E scans can help identify the location, extent, and severity of anomalies in concrete elements (i.e., detect voids, cracking, corrosion). This enables timely, data-driven decisions on when and where to intervene.

Furthermore, NDT-E methods can help project managers with effective tools in verifying the quality of repair materials, and assess the bonding between the repair concrete and the base concrete.

Real-Time Insights Through SHM

Where NDT-E provides a snapshot in time, SHM offers a live feed. Sensors embedded in concrete or wrapped around cables can track strain, temperature, or crack formation and growth in real-time. Wireless sensor networks can cover entire bridge spans or tunnel sections, collecting valuable data on movement, vibration, or load response. With recent advances in sensors, and wireless connectivity, SHM is very well positioned to be implemented in the maintenance programs for major transportation infrastructure. These systems are especially useful for high-value assets or those exposed to extreme conditions—like seismic zones or high-traffic corridors. While the upfront cost of implementing SHM systems may be high, the potential cost (and life) savings through early warning capabilities and reduced inspection needs is more significant.

Turning Data into Decisions: Integration with Asset Management

One of the most promising developments in infrastructure management is the integration of NDT and SHM data into digital asset management systems. When inspection data is stored, organized, and visualized in a consistent format, it becomes easier to compare across sites, track trends over time, and make informed decisions (see FHWA infoBridge).

By connecting this data to geographic information systems, inspection managers can map deterioration hotspots. When paired with weather, traffic, and environmental data, this information can be used to predict deterioration rates using machine learning models.

These insights help prioritize maintenance and budget allocation. Instead of reacting to failures or relying solely on fixed inspection intervals, agencies can move toward predictive maintenance strategies – fixing the right assets, at the right time, for the right reasons.

Conclusion

As construction materials and techniques evolve, so too must the tools we use to inspect and maintain infrastructure. Structures built with new materials such as UHPC, GFRP, or fiber-reinforcement present challenges that traditional inspection methods weren’t designed to handle.

Advanced NDT-E methods, paired with SHM technologies and integrated data systems, offer a smarter way forward. They enable better quality control during construction, earlier detection of deterioration during service life, and more targeted, effective repairs when needed.

References

- ACI (American Concrete Institute) Committee 228. (2013). ACI 228.2 R-13, Report on Nondestructive Test Methods for Evaluation of Concrete in Structures. ACI. Farmington Hills, MI, USA.

- Federal Highway Administration (FHWA) Bridge Deck Preservation Tool (BDPT). At https://infobridge.fhwa.dot.gov/Home (last visited on 9 Aug 2025)

- Grosse, C.U., Algernon, D., Arndt, R., Feistkorn, S., Niederleithinger, E. and Taffe, A. (2023), Some developments in the field of non-destructive testing – new devices and techniques, industrial training and academic education. ce/papers, 6: 1443-1451. https://doi.org/10.1002/cepa.2875

- Gu, P.; Beaudoin, J. J., (1987, Obtaining effective half-cell potential measurements in reinforced concrete structures, National Research Council of Canada

- Malla, Pranit, Seyed Saman Khedmatgozar Dolati, Jesus D. Ortiz, Armin B. Mehrabi, Antonio Nanni, and Kien Dinh. 2023. “Feasibility of Conventional Non-Destructive Testing Methods in Detecting Embedded FRP Reinforcements” Applied Sciences 13, no. 7: 4399. https://doi.org/10.3390/app13074399

- SHRP2 (Strategic Highway Research Program). 2013. Nondestructive testing to identify concrete bridge deck deterioration. Washington, DC: Transportation Research Board of the Academies.