FPrimeC Solutions provides innovative non-destructive testing and monitoring solutions for cost-effective and reliable inspection and testing of concrete dams.

Our NDT solutions can help customers with surface and sub-surface inspection and monitoring of concrete dams, waterways and spillways:

- Detect Major voids and discontinuities

- Detect poor quality concrete

- Map freeze-thaw damage in concrete dams

- Identify and Quantify Alkali-Silica Reactions

- Corrosion Inspection and Monitoring

Ultrasonic Scanning

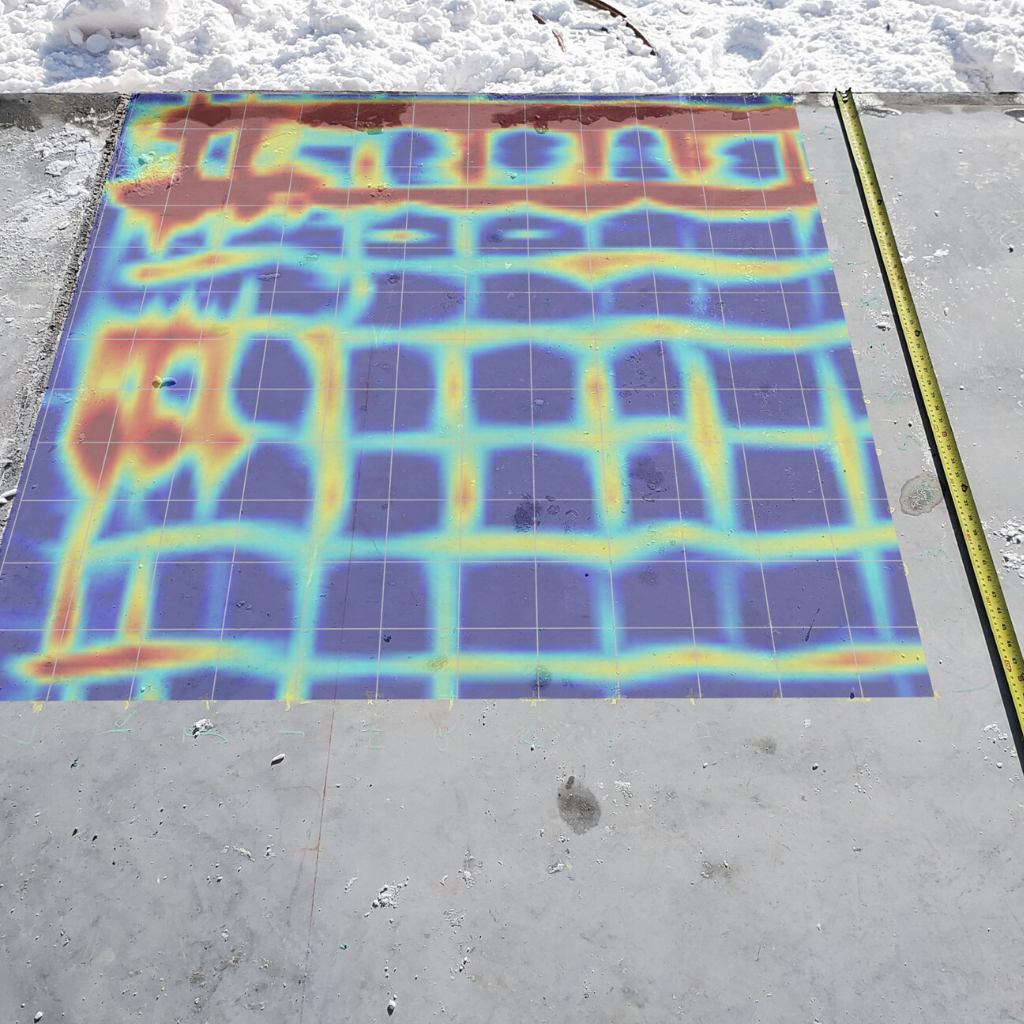

FPrimeC Solutions provides advanced ultrasonic testing solutions to scan existing surface defects (crack depth), and pinpoint sub-surface defects and anomalies.

- Crack Depth Measurement

- Evaluate depth and width of surface cracks

- Quantitative analysis of extent of concrete cracking and damage index

- Quality Control/Quality Assurance of Cold Joints

- Detect Sub-Surface Voids and Defects

- identify location of major voids

- identify extent of Honeycombing

- identify homogeneity and consistency issues

Read More: Ultrasonic Testing of Concrete

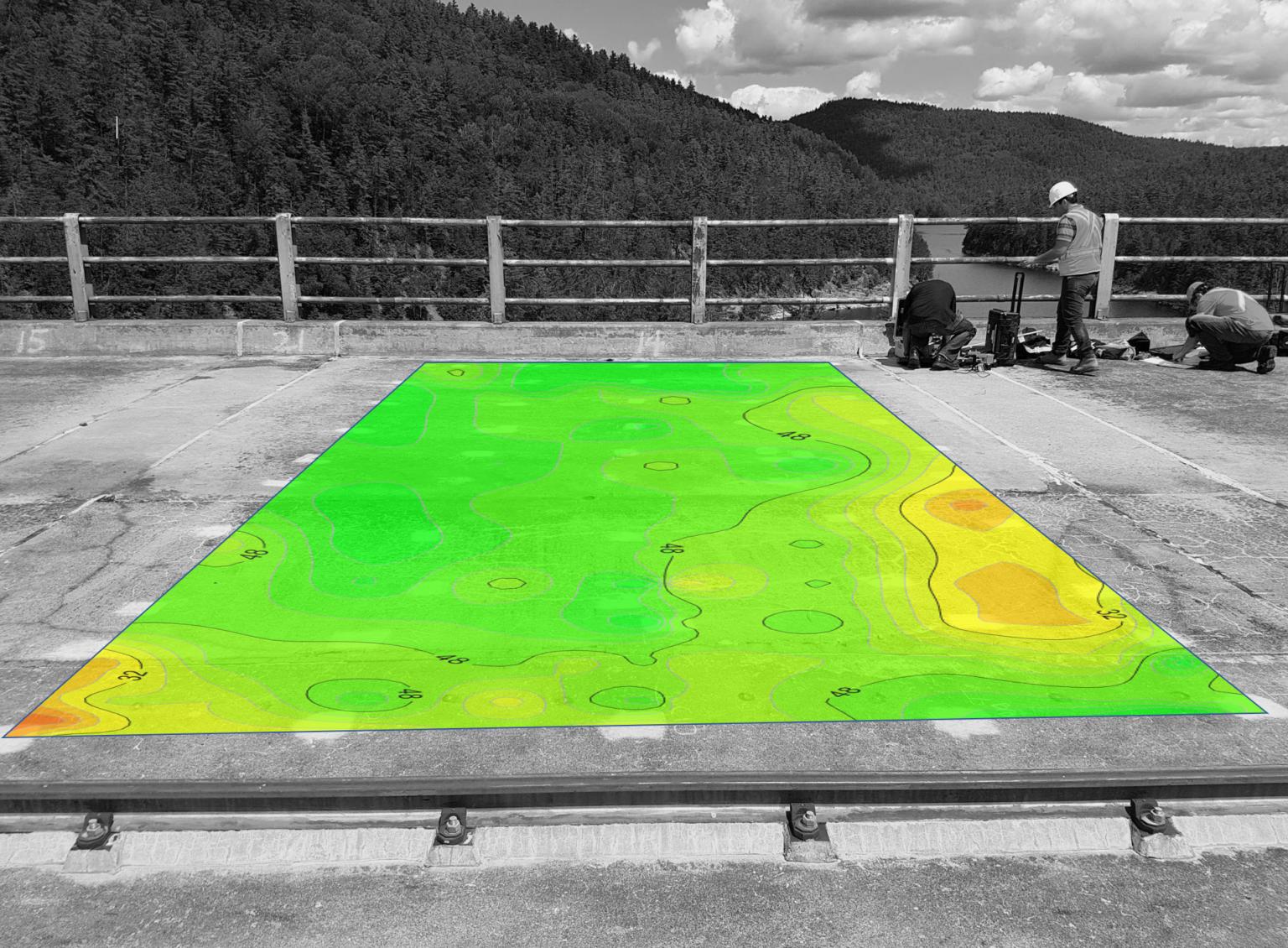

Impact-Echo and Impulse-Response Scanning

Impulse-Response Methods (Transient Method) and Impact-Echo provide a great too for scanning concrete elements in dams, and spillways.

Impact echo is a great method to identify the depth and location of delamination in concrete slabs, and spillways.

Impulse-Response method is used to locate voids and defects underneath the concrete slabs.

Ground Penetrating Radar

FPrimeC Solutions provides expert data collection & superior ground penetrating radar solutions tailored to your unique challenge. Weather you are scanning concrete to locate rebar, or using GPR to identify and locate sub-surface defects, our NDT experts can help you.

- Pinpoint Structural Detail

- locate steel rebar

- locate post-tensioning tendons

- locate conduits and pipes

- estimate the cover thickness

- estimate concrete thickness

- Detect Sub-Surface Voids

- identify location of major voids

- locate cavities

Read More: Ground Penetrating Radar