Non-Destructive Evaluation of Concrete Culvert

Civil infrastructure, particularly underground water conveyance structures like culverts, faces constant challenges from environmental exposure, moisture ingress, and aging. Ensuring the structural integrity of these assets is critical to preventing service disruptions and maintaining public safety. While visual inspections can identify surface defects, they often fail to reveal the full extent of internal deterioration such as hidden voids, delamination, or reinforcement corrosion.

FPrimeC Solutions was engaged to perform a comprehensive Non-Destructive Evaluation of Concrete Culvert in Waterloo, ON. The main objective was to assess the extent of delamination and identify potential sub-surface anomalies.

The Challenge

The project site involved a concrete culvert structure where visual signs of deterioration and delamination had previously been reported. The client identified specific “Test Stations” located at varying distances along the culvert. These areas generally featured joints and other openings (catch basins), which are typically vulnerable points for water ingress and subsequent premature concrete degradation. The primary engineering challenges were:

- Quantifying the Damage: Moving beyond visual confirmation to accurately map the depth and extent of delamination around joints and openings.

- Assessing Concrete Quality: Determining if the visible deterioration was localized to the joints or symptomatic of widespread concrete issues across the soffit.

- Non-Invasive Approach: The assessment needed to be conducted without damaging the existing structure, using advanced NDT methods to “see” inside the concrete.

The Solution: Multi-Method NDT Approach

To provide a holistic assessment, FPrimeC Solutions employed a multi-technology Non-Destructive Evaluation of Concrete Culvert by combining Ground Penetrating Radar (GPR) and Ultrasonic Pulse Testing. This combination allowed for cross-verification of results, ensuring a higher confidence level in the findings.

1. Ground Penetrating Radar (GPR)

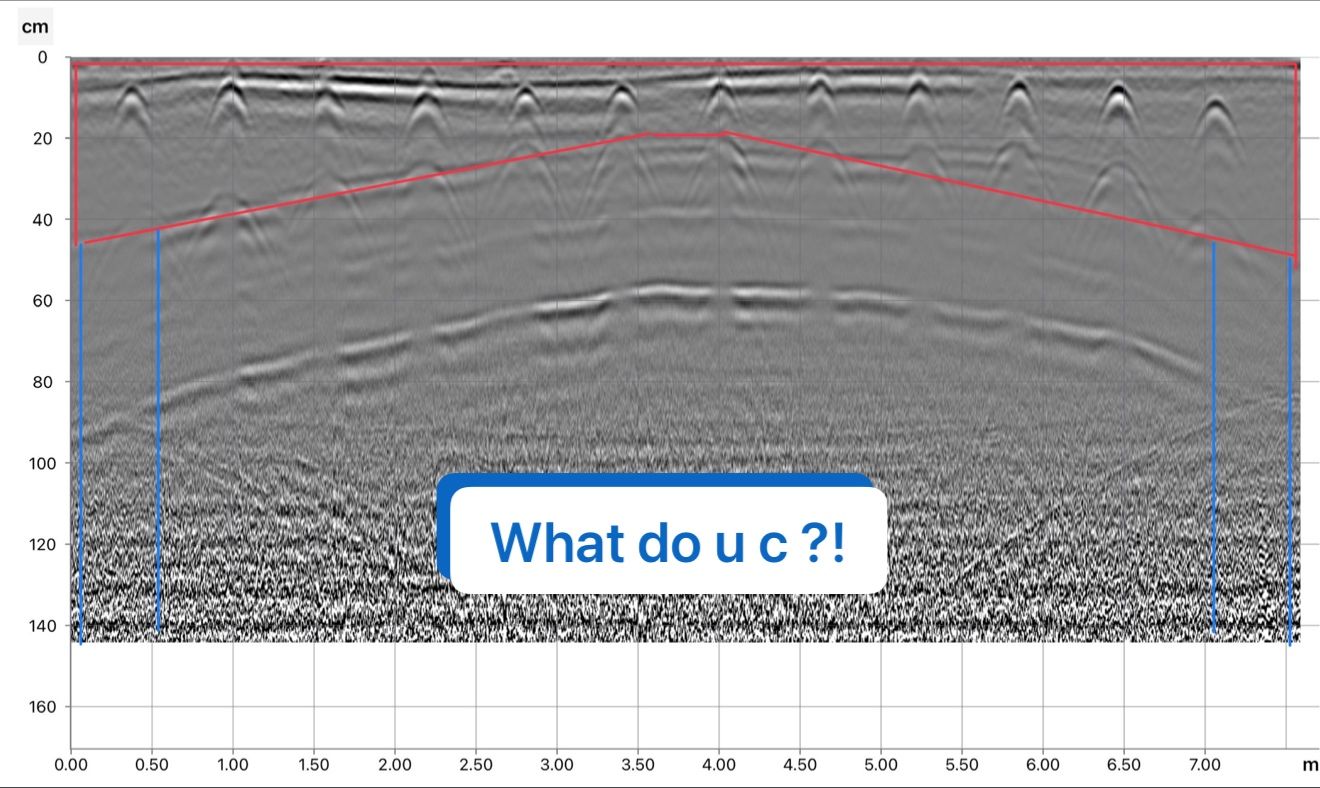

GPR scans were performed on the culvert soffit to detect subsurface anomalies.

- Purpose: To identify delamination, map reinforcement layout, and detect potential corrosion in the rebar.

-

Methodology: Scans were conducted along grid lines at each station. The data was analyzed for specific signal patterns—such as “high amplitude” reflections indicating delamination (air gaps) or “low intensity” hyperbolas suggesting corroded rebar. GPR scans showed high-contrast reflections above the rebar layer in affected zones, confirming significant separation within the concrete. However, scans taken further away from these joints did not show signs of progressive deterioration, suggesting the issues have not spread extensively.

2. Ultrasonic Pulse Testing

UPV testing was utilized to assess the general quality and uniformity of the concrete.

-

Purpose: To detect internal voids, cracks, and honeycomb areas that might not be visible to the naked eye.

-

Methodology: An “Indirect” transmission configuration with 0.3 m probe spacing was used. The velocity of ultrasonic pulses through the concrete was measured and correlated to concrete quality (e.g., velocities >4,500 m/s indicate “Excellent” quality, while <2,100 m/s indicates “Very Poor” quality).

Conclusion

The Non-Destructive Evaluation of Concrete Culvert successfully quantified the extent of the damage without invasive measures. The findings provided the client with the assurance that the widespread concrete body is sound, while precisely pinpointing the zones requiring repair.

By utilizing GPR and UPV, FPrimeC Solutions demonstrated that the defects were localized to vulnerable joint and opening locations. This data-driven insight allows the client to focus maintenance budgets on targeted repairs rather than unnecessary widespread rehabilitation, ensuring the continued safe operation of this critical infrastructure asset.