Ultrasonic Testing of Concrete – How it works?

The concept behind the technology is measuring the travel time of acoustic waves in a medium, and correlating them to the elastic properties and density of the material. Travel time of ultrasonic waves reflects internal condition of test area. In general, for a given trajectory, higher travel time is correlated to low quality concrete with more anomalies and deficiencies, while lower travel time is correlated to high quality concrete with fewer anomalies. Once ultrasonic wave spreads within the test area, the wave is reflected in boundary of anomalies resulting in higher travel time. This results in higher transmission time (lower wave speeds) in poor quality concrete and lower transmission time (higher wave speed) in good quality concrete.

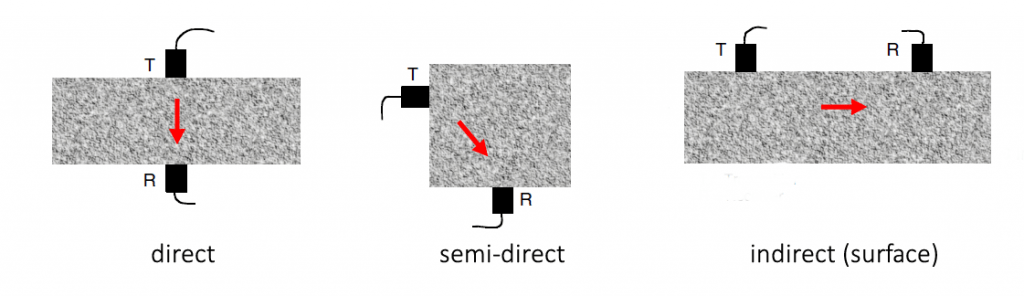

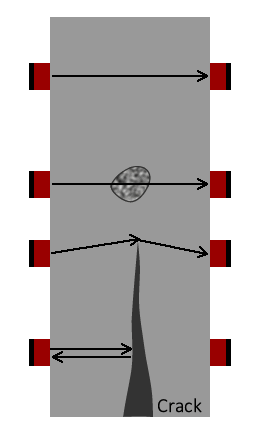

Different configurations of transducers can be used to perform a UPV test. This includes direct transmission, semi-direct transmission, and indirect (surface) transmission. Figure above shows different configurations of transducer based on the access to the surface of test area. The ultrasonic velocity is prone to signal travel trajectory that is defined by the transducer configurations. Figure below is a representation of the effect of concrete anomalies and deficiencies on the acoustic wave travel time and the corresponding velocity throughout a given trajectory (ACI 228.2R, 2013).

Different configurations of transducers can be used to perform a UPV test. This includes direct transmission, semi-direct transmission, and indirect (surface) transmission. Figure above shows different configurations of transducer based on the access to the surface of test area. The ultrasonic velocity is prone to signal travel trajectory that is defined by the transducer configurations. Figure below is a representation of the effect of concrete anomalies and deficiencies on the acoustic wave travel time and the corresponding velocity throughout a given trajectory (ACI 228.2R, 2013).

Couplant | Concrete-Transducer contact

The UPV transducers must be in full contact with the concrete surface; otherwise the air pocket between the transducer and concrete may result in measurement error (i.e. inacurate measurement of transit time). One reason is that only negligible amount of wave energy will be transmitted in a poor contact. Different couplants can be used to eliminate air pockets and to assure good contact (e.g. petroleum jelly, grease, liquid soap, and kaolin-glycerol paste). It is recommended to make the couplant layer as thin as possible.

Applications of UPV Testing for Concrete

Several researchers and engineers have studied the use of ultrasonic testing of concrete in different engineering projects:

1- Pulse Velocity Determination

2- Concrete Quality Assessment (learn more)

3- Establishing Homogenity and Uniformity of Concrete

4- Measurement of Surface Crack Depth (read more)

5- Prediction of Compressive Strength of Concrete (read more)

UPV – Influencing Parameters

In order to conduct a reliable ultrasonic testing of concrete, the surface of concrete should be clean, and free of dust. A suitable couplant is needed to establish an ideal connection between concrete and UPV transducers. Special attention should be given to rebar in concrete, since the wave travel speed in metal is much higher than in concrete. The interpretation of test results in heavily reinforced concrete is somewhat difficult. The direct configuration is the most ideal for getting reliable readings; however, the use of this configuration is mainly limited to laboratory. In summary, the following issues should be addressed before, during, and after performing the test:

1- Concrete Properties (aggregate size, type, and content)

2- Transducer Contact/couplant material

3- Presence of Rebar

4- Sensor Configuration

Muhammad Salman Jafry

V. Good but need more precious because rejection & approval of concrete required solid evidence.

FPrimeC

Muhammad,

Rejection and approval is normally done based on approved standard test procedure such as concrete cylinders and cores.

When taking such samples is not possible, NDT methods can be used to study these structure. such cases will be existing structures with defects. coring and damaging will put structure integrity at risk.

Gorodn

Muhammad,

The concrete strength test is only good for determining the laboratory strength of concrete. UPV aids in:

1. how uniform is the concrete?

2. is the concrete damaged?

3. are there any voids?

A sample helps get quantitative results. It depends an what your are trying to do.

Many years ago I was asked if piles should be rejected on the basis of the laboratory concrete sample test. My question to the field was "were the piles damaged during driving"?

Tarek Aly Elsayed

This is a very intreasting issue as NDT is very essential espcially for concrete repair, strengthening, and retrofitting, where the actual mechanical properties and residual strength is deeply needed. For concrete flaws, UPV is an excellent technique. But the UPV needs enhancements to get strong and higher confidence results espcially for strength values. Would you till us how to enhance the UPV results.

3 Methods for Crack Depth Measurement in Concrete | FPrimeC Solutions

[…] Ultrasonic Pulse Velocity (UPV) is an effective non-destructive testing (NDT) method for quality control of concrete materials, and detecting damages in structural components. The UPV methods have traditionally been used for the quality control of materials, mostly homogeneous materials such as metals and welded connections. With the recent advancement in transducer technology, the test has been widely accepted in testing concrete materials. Ultrasonic testing of concrete is an effective way for quality assessment and uniformity, and crack depth estimation. The test procedure has been standardized as “Standard Test Method for Pulse Velocity through Concrete” (ASTM C 597, 2016). To learn more about UPV method, and its applications, click here […]

Smita Kale

It was great to read this testing method. Thanks for sharing this useful blog.

4 Methods of Condition Survey for Bridge Decks | FPrimeC Solutions

[…] Ultrasonic Pulse Velocity (UPV) is an effective non-destructive testing (NDT) method for quality control of concrete materials, and detecting damages in structural components. The UPV methods have traditionally been used for the quality control of materials, mostly homogeneous materials such as metals and welded connections. With the recent advancement in transducer technology, the test has been widely accepted in testing concrete materials. Ultrasonic testing of concrete is an effective way for quality assessment and uniformity, and crack depth estimation. The test procedure has been standardized as “Standard Test Method for Pulse Velocity through Concrete” (ASTM C 597, 2016). […]

5 NDT Methods for Structural Evaluation | FPrimeC Solutions

[…] Learn more Ultrasonic Testing of Concrete […]

Carlos Aliaga

A very well explained post, thanks for sharing.

I have one question; What about the effect of the signal when you have cold joints? (Cold joints are formed primarily between two batches of concrete where the delivery and placement of the second batch has been delayed and the initial placed and compacted concrete has started to set)

We know that Cold Joints perform poorly when transmitting the vibration energy generated by the machine.

Do you have data about that?

Thanks in advance.

Carlos A.

Joshua Legarde

Dear all. The question is for my thesis, I want to know, if I have a set of signals recorded from UPV testing with a 54 kHz P trasducers, How can I perform a VELOCITY MAP of the concrete prism?

Dr Farhad Nabavi

Hi Joshua,

To achieve velocity map you should use Area Scan (A-Scan) method utilising Ultrasonic Pulse-Echo.

Johan

Hi guys,

I am an ultrasonic level II technician for steel and have 40 years + experience in the trade. I was, however, contacted by a company here to try and sort out their CONCRETE UT MACHINE!! I am honest if I say that I do not know anything about concrete testing but would really like to help them out as they do not have a clue how to operate the machine and the job was dumped on them. My company do the NDT on the pipe work and they must do the concrete testing. Is it possible somebody that is willing to guide me through the calibration process of the machine with some hints

Thanks a million in advance

Johan Gous

How To Estimate Strength of Concrete Using NDT Methods? | FPrimeC Solutions

[…] Ultrasonic Pulse Velocity (UPV) is an effective method for quality control of concrete materials, and detecting damages in structural components. The UPV methods have been traditionally used for the quality control of materials, mostly homogeneous materials such as metals and welded connections. With the recent advancement in transducer technology, the test has been widely accepted in testing concrete materials. The test procedure has been standardized as “Standard Test Method for Pulse Velocity through Concrete” (ASTM C 597, 2016). The concept behind the technology is measuring the travel time of acoustic waves in a medium, and correlating them to the elastic properties and density of the material. Travel time of ultrasonic waves reflects internal condition of test area. Some researchers have tried to develop a relationship between the strength and wave speed. Read More About UPV Method […]

ABINAYA

DOES ULTRASOUND PASSES THROUGH COCONUT SHELL?

Kazmi

What is the effect of particle size and particle size distribution on UT echoes obtained? Is it possible that not a single echo is obtained during testing?

Non-Destructive Testing for Structural Condition Assessment | FPrimeC Solutions

[…] can be used to evaluate the structural integrity and locate potential defects in structures. Ultrasonic testing of concrete provides a cost-effective approach to evaluating concrete material, and crack depth in concrete […]

Non-Destructive Testing for Detailed Bridge Condition Survey | FPrimeC Solutions

[…] to concrete strength, combined NDT methods can be used. A combination of rebound hammer and ultrasonic pulse velocity can help engineers estimate the strength of concrete. The method can help reduce the number of […]

Non-Destructive Evaluation of Cold Joints in Concrete | FPrimeC Solutions

[…] Ultrasonic Pulse Velocity (UPV) is an effective non-destructive testing (NDT) method for quality control of concrete materials, and evaluating concrete integrity on or around the cold joint. Ultrasonic testing of concrete is an effective way for quality assessment and uniformity, and crack depth estimation. The test procedure has been standardized as “Standard Test Method for Pulse Velocity through Concrete” (ASTM C 597, 2016). </ […]

Elumalai.S

we are fabricated and erected precast concrete elements, But we are not witnessed at that time of fabrication,ND test (Ultrasonic pulse velocity) suitable for precast elements,Kindly explain.

5 Methods for On-Site Evaluation of Concrete Strength | FPrimeC Solutions

[…] Ultrasonic Pulse Velocity (UPV) is an effective method for quality control of concrete materials, and detecting damages in structural components. The UPV methods have been traditionally used for the quality control of materials, mostly homogeneous materials such as metals and welded connections. With the recent advancement in transducer technology, the test has been widely accepted in testing concrete materials. The test procedure has been standardized as “Standard Test Method for Pulse Velocity through Concrete” (ASTM C 597, 2016). The concept behind the technology is measuring the travel time of acoustic waves in a medium, and correlating them to the elastic properties and density of the material. Travel time of ultrasonic waves reflects internal condition of test area. Some researchers have tried to develop a relationship between the strength and wave speed. […]

vineeth

Hi sir,

This is vineeth persuing bachelor of engineering from vasavi college of engineering from civil engineering stream.

" Sir we are trying to do project on health monitoring of structures so we need the equipment that you are shown here"

Dr. Ferhad R. Karim

I used UPV for more than 4000 times. I encounter a problem from UPV now which is the word "overflow" instead giving us the transit time.

Non-Destructive Evaluation of Cracking in Concrete Beams | FPrimeC Solutions Inc.

[…] […]

3 Methods for Crack Depth Measurement in Concrete | FPrimeC Solutions Inc.

[…] learn more about UPV method, and its applications, click here. UPV method can be used for estimating the depth of surface cracks. To do so, each transducers […]

Alicia Byrne

I didn't know that we can use ultrasonic testing for determining the quality of the concrete. My husband was talking to me about determining the strength and quality of the concrete walls. I will let him know that there's something called ultrasonic testing that can help with quality assessments for concrete.

NDT Methods for Concrete Imaging and Scanning | FPrimeC Solutions Inc.

[…] tomography is a special test setup based on the very concept of Ultrasonic Pulse Velocity. In this method, an array of multiple receiving transducers are placed and fixed in the test […]

Ultrasonic Pulse Echo Tomography for Concrete | FPrimeC Solutions Inc.

[…] from concrete. The test method was developed to address practical limitations of the general Ultrasonic Pulse Velocity test, such as the need to access both sides of the concrete […]

PCTE

The article is informative about the Ultrasonic Testing of Concrete Images, and the videos are helpful. Thanks for such valuable information.

Shari

Can this equipment for Ultrasonic Testing be used on different types of materials? Like ceramics, plastics, or metals?

Mason

Great to read this testing method! The images and the video are helpful. Thanks for this useful information.

Non-destructive Evaluation of Concrete in Mine Facilities - FPrimeC Solutions Inc.

[…] Ultrasonic Pulse Velocity family can be used to assess the overall quality and uniformity of concrete elements in the […]