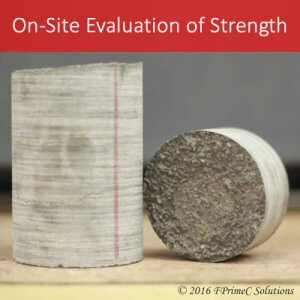

In this article, we will briefly review how to Estimate Strength of Concrete Using NDT Methods. Compressive strength of concrete is by far the most important property of concrete. It represents the mechanical properties of concrete; for example, the 28 days compressive strength of concrete cylinders is the key parameter in most design codes (ACI 318-14, CSA A23.3-14). Concrete strength is found to have reasonable relationship with certain durability parameters of concrete. For example, it is expected that high strength concrete also has good durability parameters.While compressive strength of concrete can easily be determined in the lab, estimating the strength value for hardened concrete in the field remains a challenge. On-site evaluation of concrete strength is a main challenge in the condition assessment of existing infrastructure. Owners and managers of such facilities prefer non-destructive methods to avoid further damage to an already struggling structure.

What is Compressive Strength of Concrete?

Compressive strength of concrete is determined using the classic compression test. Concrete cylinders or cubes are placed in the compression machine. The stress is gradually increased until the concrete specimen breaks. This is normally considered as the strength of concrete sample. In the design codes, the strength of concrete samples at the age of 28 days after casting is considered as the minimum compressive strength. This is the value that is used for design of new structures.

For existing structures, core samples are taken from the existing elements and tested for compressive strength. This is considered the most reliable method to estimate the compressive strength. However, this method has certain limitations mainly because:

1) It is destructive. Not only it damages concrete integrity, it might affect reinforcing bars in RC structures. Rebar locating tools are needed to avoid this problem.

2) Selecting test locations can be difficult. Selecting the best location of cores is relatively subjective.

3) The locations of cores needs to be repaired.

4) Coring is not an option for owners of important structures, especially when there are concerns about further damaging the structure.

How To Estimate Strength of Concrete Using NDT Methods?

Non-destructive test methods have been developed over the years to estimate the strength of concrete. The following provides a brief review of these test methods, their application and limitation for reliable prediction of concrete strength.

Pull Out Test

The concept behind this method is that the tensile force required to pull a metal disk, together with a layer of concrete, from the surface to which it is attached, is related to the compressive strength of the concrete.The pull out test is normally used for early diagnosis of strength problems. However, it can be used to evaluate the strength of concrete in existing structures. Pull out testing involves attaching a small piece of equipment to the exterior bolt, nut, screw or fixing. This is then pulled to the designated stress load level to determine how strong and secure the fixing is.

Advantages of Pull Out Test

1) Relatively easy to use.

2) If relationship to strength is established, the method can deliver robust test results.

Disadvantages of Pull Out Test

1) It involves crushing and damaging concrete

Rebound Hammer

The methods based on the rebound principle consist of measuring the rebound of a spring driven hammer mass after its impact with concrete. The test has been widely used, since its introduction in 1948. The main reason behind its popularity, is its simplicity, and convenient of use for field applications. Rebound hammer is used to evaluate the surface hardness. Malhotra (2004) argues that “there is little apparent theoretical relationship between the strength of concrete and the rebound number of the hammer. However, within limits, empirical correlations have been established between strength properties and the rebound number.” The test method has been standardized through ASTM C 805. To use this test method to estimate strength, it is necessary to establish a relationship between strength and rebound number for a given concrete and given apparatus. Such relationship can be established by correlating rebound numbers measured on the structure with

the measured strengths of cores taken from corresponding locations.

Advantages of Rebound Hammer

1) It is easy to use for most field applications.

2) The test can be used to study the uniformity of concrete

Disadvantages of Rebound Hammer

1) The method is very subjective

2) surface condition, presence of rebar, presence of sub-surface voids can affect the test results

Ultrasonic Pulse Velocity (UPV)

Ultrasonic Pulse Velocity (UPV) is an effective method for quality control of concrete materials, and detecting damages in structural components. The UPV methods have been traditionally used for the quality control of materials, mostly homogeneous materials such as metals and welded connections. With the recent advancement in transducer technology, the test has been widely accepted in testing concrete materials. The test procedure has been standardized as “Standard Test Method for Pulse Velocity through Concrete” (ASTM C 597, 2016). The concept behind the technology is measuring the travel time of acoustic waves in a medium, and correlating them to the elastic properties and density of the material. Travel time of ultrasonic waves reflects internal condition of test area. Some researchers have tried to develop a relationship between the strength and wave speed. Read More About UPV Method

Advantages of UPV

1) UPV can be used to detect other sub-surface deficiencies

Disadvantages of UPV

1) The method is affected by presence of rebar, voids, and cracks.

2) There is no enough results for assessing the reliability of the method in the field.

5- Combined Methods

Combined methods involves a combination of NDT methods for predicting the on-site strength of concrete. The combination of UPV and Rebound hammer has been studied by several researcher. The combined methods often deliver more comprehensive results. The improvement of the accuracy of the strength prediction according is achieved by the use of correction factors taking into account the influence of cement type, cement content, petrologic aggregate type, fine aggregate fraction, and aggregate maximum size. The accuracy of the combination of rebound hammer and ultrasonic pulse velocity results in improved accuracy in estimating the compressive strength of concrete (Hannachi and Guetteche, 2012)

Dale Fietz

There is one more way of obtaining the compressive strength of concrete in place.

The tried and true method, measure the resistance to force and plot deformation vs. load.

I have determined the best penetration load head is as described in ACI SP-82 "Point load test" by PJ Robbins. A load cell measures the force produced by a hydraulic ram and a sensor that measures the displacement of the load head as load is applied, completes all that is needed to plot the secant modulus.. Can be used in any void where there are two opposite faces; blockouts for plumbing, electrical, fire risers or 4 inch core sample holes.

Regards,

Dale H. Fietz P.E., M. ASCE

Sam Li

I love what you mentioned about combined methods and how they involving using NDT methods to predict concrete strength. Non-destructive testing is convenient because you receive accurate data without letting anything go to waste. If I were to need such services, I would make sure to contact a company in town that can perform non-destructive testing in a timely manner.

Timothy uche

Thanks for the information you have cleared my doubts. Pls send me the standard speed of waves on plain concrete's. Thanks

5 Methods for On-Site Evaluation of Concrete Strength | FPrimeC Solutions

[…] Concrete strength (compressive strength) is by far the most important property of concrete. It represents the mechanical properties of concrete; The 28 days compressive strength of concrete cylinders or cube samples has widely been accepted as the minimum specified concrete strength in most design codes (ACI 318-14, CSA A23.3-14). Concrete Strength is also considered (at least in the old school) a key factor for durability performance and design for performance. The following will take a quick look at the most conventional test (concrete compression test on concrete samples or cores), as well as some of the major non-destructive testing solutions for evaluation of concrete strength. […]

defensive driving school lubbock tx

You have made some decent points there. I checked on the web to learn more about the issue and found most individuals will go along with your views on this web site.|

Noorullah

We can't do exact calculations in these tests but we can get the approximate quantity but the problem still exists. How can we find economic tests without this test?

These devices are expensive and are not available everywhere.