Rebound Hammer

The Schmidt rebound hammer test is a non-destructive testing apparatus, whereby the rebound of the spring driven mass is measured after its impact with concrete surface. The output of the rebound hammer is referred to as rebound number and are correlated with surface hardness of concrete.

A commercial rebound hammer includes a plunger that is pushed against the concrete, perpendicular to the surface. As the hammer body is pushed towards the concrete, the force of the causes the latch to release, and make an impact on the concrete. At this point, the hammer impacts the shoulder of the plunger rod & rebounds. During the rebound the slide indicator is moved from the hammer mass, and the rebound distance is recorded.

The hammer can be placed in many configurations; upwards, downwards, horizontal vertical & at any intermediate angle. Commercial devices in the market use different means to display the rebound number after each strike.

Older generation devices displays the rebound number through a mechanical slider. Nowadays, most modern hammers use electrical or even wireless means of displaying the results on data loggers, or smart devices such as a tablet.

Applications of Rebound Hammer

The main application of a rebound hammer is to measure the hardness of concrete using the rebound principle. However, researchers have tried to use the method to assess different properties of concrete. Among them, the following applications are widespread:

Assess the in-place uniformity of concrete

Delineate regions in a structure of poor quality or deteriorated concrete

As an in-place method to Estimate Concrete Strength

Among these applications, using rebound hammer to estimate strength of concrete has remained the most controversial use. Researchers are divided when it comes to evaluating concrete strength by the use of rebound hammer.

Key Information for Successful Rebound Hammer Measurement

There are few key steps in performing the Rebound Hammer test:

Preparing Test Surface

Inspectors should pay attention to the following considerations prior to conducting a rebound hammer test:

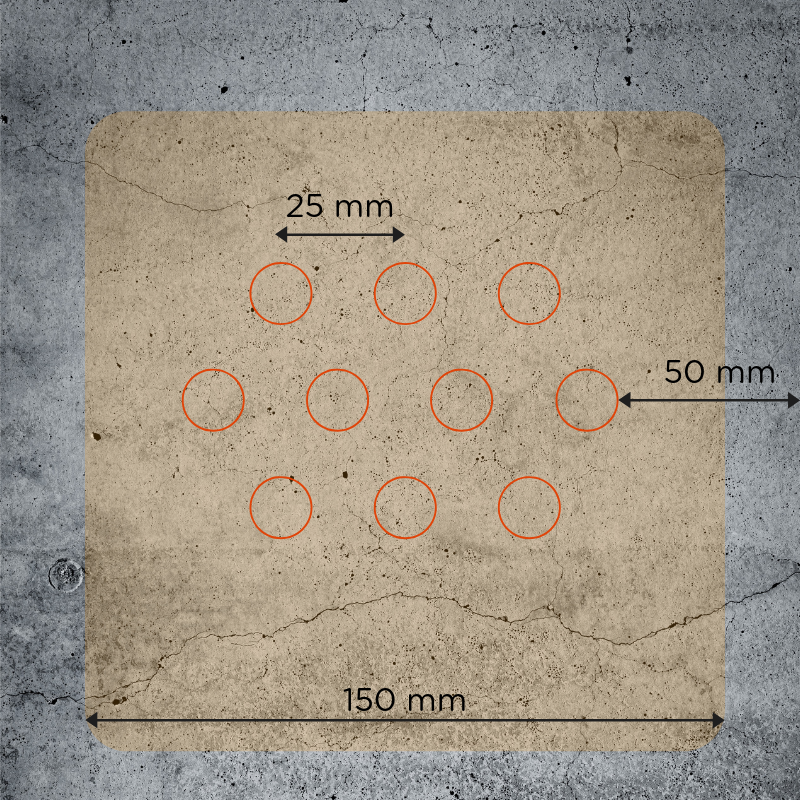

- The testing surface must be at least 150 mm diameter.

- Ground concrete surface (until its flat) if it is heavily textured or contains loose mortar. Note: It is essential to know that the results from prepared surface are generally not comparable to those obtained from unprepared surfaces.

- If there is any free moisture or water on the concrete surface, it must be removed prior to testing.

- Do not test frozen concrete. Note: Concrete should only be tested after it has thawed, since frozen concrete tends to have high rebound numbers.

- Avoid direct testing over steel reinforcement when cover thickness is less than 20 mm. It is recommended to use a rebar locator to avoid testing on shallow depth reinforcement.

Number of Readings

- In order to ensure accuracy, 10 readings should be taken from each test area.

- In addition, the distances between impact points should be at least 25 mm,

- The distance between impact points and edges of the member should be at least 50 mm.

It is also important to note that if the impact crushes or breaks through a near surface air void the reading must be disregarded and another reading should be taken.

Standards and Guidelines

- ASTM C805, “Standard Test Method for Rebound Number of Hardened Concrete”

Please contact us for a free quotation and tell us more about your project