Ultrasonic Pulse Echo – UPE

The Ultrasonic Pulse-Echo (UPE) method is a powerful non-destructive testing method for concrete. The test can be performed on concrete elements with one side access, which makes it a primary test method for evaluating concrete or shotcrete walls, and tunnel linings.

The concept behind Ultrasonic Pulse Echo method relies on the propagation of stress waves through materials:

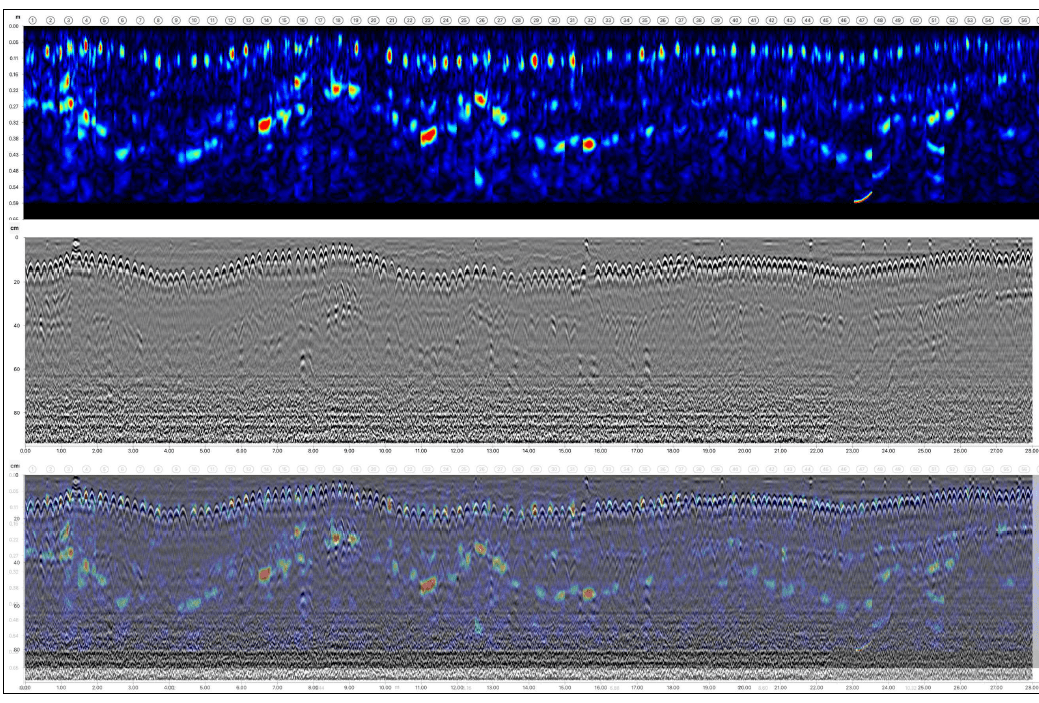

A transmitter introduces a stress pulse into the object at an accessible surface. The pulse propagates into the test object and is reflected by flaws or interfaces. The emitted impulse and the reflected acoustic waves are monitored at the receiving transducer. The signals are analyzed in the time domain, to calculate the wave travel time. If the wave speed in the material is known, this travel time can be used to evaluate the thickness of the medium. Depending on the multilayer system under investigation, the travel time of shear or compressive waves is used to evaluate the thickness of each layer (ACI Committee 228.2R.

Ultrasonic Pulse Echo method is a powerful tool and can be used for:

- Estimate the thickness of concrete elements;

- Identify delamination and major cracks in concrete;

- Identify the location and extent of voids and honeycombing;

- Evaluation the integrity of concrete

Estimate Concrete Thickness

UPE is primary choice when it comes to estimating the concrete thickness in concrete elements with one side access. This is often the case in concrete tanks, tunnel lining, water and wastewater pipes.

Detect Flaws in Concrete and Shotcrete

Ultrasonic Pulse Echo is a powerful technique for evaluating concrete or shotcrete deficiencies.

In new construction, UPE can be used for Quality Assurance of concrete to detect poor consolidated concrete (honeycombing), and cold joints. In shotcrete construction, UPE can effectively be used to detect the location of voids and poor bond between shotcrete layers.

Please contact us for a free quotation and tell us more about your project