Quality Verification Engineering

FPrimeC provides a wide range of inspection, and testing services as part of Quality Verification Engineering in Construction projects.

Benefits of Quality Verification Engineering

- For Asset Owners

Reduces latent defects

Avoids costly future failures

Supports long-term asset performance

- For Designers

Confirms design assumptions

Provides feedback for future projects

- For Contractors

Protects against unjustified rejection

Provides objective, data-backed acceptance

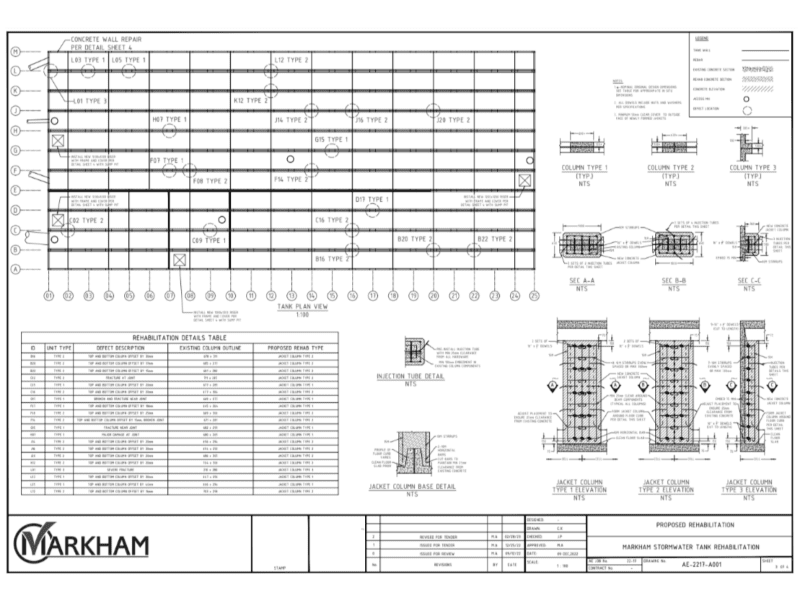

Pre-Construction Quality Planning & Risk Identification

PrimeC supports project teams early by identifying quality-critical elements and construction risks before work begins. Our engineers review drawings, specifications, and exposure conditions to help define appropriate verification strategies for concrete placement, reinforcement layout, and durability requirements.

Value to the project:

Reduces rework and disputes

Aligns quality expectations across stakeholders

Focuses verification where it matters most

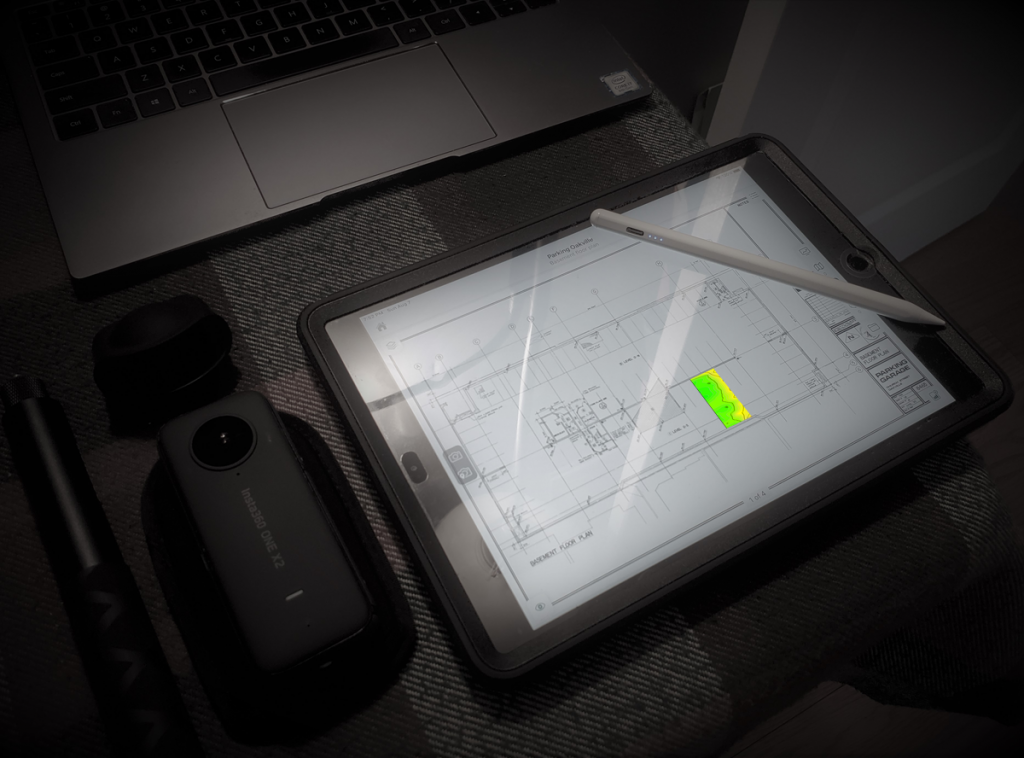

Verification of Reinforcement Layout, Cover, and Embedments

Using advanced non-destructive testing methods such as GPR and electromagnetic scanning, FPrimeC verifies reinforcement location, spacing, and concrete cover in newly constructed elements. This is particularly valuable before coring, post-installed anchors, or concealment of critical elements.

Value to the project:

Confirms compliance with design intent

Prevents costly corrective work

Provides documented quality records

In-Situ Concrete Quality and Uniformity Assessment

FPrimeC applies engineering-guided NDT techniques to assess concrete quality, uniformity, and consolidation without damaging newly constructed elements. Results are interpreted by engineers and correlated with construction practices and mix design—not used in isolation.

Value to the project:

Early identification of potential quality issues

Avoids unnecessary destructive testing

Supports acceptance decisions

Quality Verification Engineering – Pile Integrity Tests

FPrimeC provides a wide range of non-destructive testing for quality verification of quality and integrity for the deep foundations, concrete piles (caissons). FPrimeC provides end to end Quality Verification Engineering for test, installing sensors, performing pile integrity tests, signal interpretation, and identification of defects.

- Visual Scanning of Borehole and Caissons

- Pile Integrity Test or Low Strain Pile Integrity Test: (PIT)

- Crosshole Sonic Logging (CSL)

- Thermal Integrity Profiling (TIP)

- Shaft Quantitative Inspection Device (SQUID)

- SoniCaliper for Shaft Verticality

Shotcrete and Specialized Concrete Installation Verification

For projects involving shotcrete, specialty mixes, or complex placement conditions, our Quality Verification Engineering package involves evaluating in-place quality using advanced NDT and targeted intrusive verification where required. Our assessments consider installation method, rebound, curing, and access constraints.

Value to the project:

Reduces uncertainty in difficult-to-inspect work

Supports acceptance of concealed construction

Strengthens documentation for close-out

Independent Third-Party Quality Verification

As an independent engineering firm, FPrimeC provides objective QVE services for owners, lenders, and project stakeholders. Our role is verification—not construction—ensuring unbiased assessment of compliance with drawings, specifications, and performance requirements.

Value to the project:

Strengthens owner confidence

Reduces disputes between parties

Provides defensible technical documentation

Please contact us for a free quotation and tell us more about your project