This article describes the applications of non-destructive testing (NDT) and evaluation in the inspection and condition assessment of Concrete tanks. Depending on their particular application, concrete tanks are exposed to water, wastewater (sewer), and other aggressive chemicals. This can result in deterioration of concrete during its life cycle. Non-destructive Testing can help engineers in evaluating the location and extent of defects.

Concrete Tanks

Inspection and Non-destructive Testing of Concrete Tanks at regular intervals will ensure the safety and reliability of these assets. The application of NDT methods for inspection and monitoring will help detect and quantify potential defects and deterioration mechanisms at an early stage. Test results will help the owners in prioritizing repair and maintenance needs, and prevent excessive damages which can have great financial and environmental impacts.

Concrete tanks in paper mill, Gatineau, QC

Challenges in Concrete Tanks

Concrete tanks are used for water storage, wastewater treatment centres, paper mills, chemical plants, and perhaps many other industrial facilities. In many cases, concrete elements are directly exposed to harsh conditions, such as:

Exposure to corrosive agents

Concrete elements in wastewater (sewage) collection and treatment facilities are subject to corrosive agents, which could result in the deterioration of concrete over time.

Exposure to Pressure and High Temperature

Concrete can be exposed to high pressure and temperature in certain chemical plants. This harsh condition can result in premature deterioration of concrete.

Environmental Loading

Environmental conditions such as weather (extreme hot/cold) can cause degradation.

It is very common to find cracks on concrete surface. While most cracks may not pose great risk to the integrity of the concrete tank, others can create shortcuts for aggressive agents to get inside concrete, and kick start the deterioration. These cracks can make a leakage path on the concrete tank.

Inspection techniques and equipment should therefore be able to identify degradation and potential total failure, as well as the more likely corrosion that leads to leakage. The main advantage of NDT methods is that these methods are minimally intrusive, and testing can be done with minimum intervention. NDT tests are repeatable, which make them ideal for regular inspection and monitoring.

Non-Destructive Testing of Concrete Tanks

Non-destructive testing of concrete tanks can help asset owners and consulting engineers identify potential surface and sub-surface defects in the concrete tanks, and minimize the number of intrusive testing.

NDT methods help engineers obtain a realistic picture of existing condition of the concrete tank, and develop better repair strategies and more accurate cost estimates. In general, the NDT methods can help to:

- identify potential location of defects,

- study the state of certain damages over the life-cycle,

- provide information about durability properties of concrete (permeability, surface electrical resistivity),

- shortening the inspection timeline, to ensure maximum productivity.

Different NDT methods can be used to obtain critical information about the existing condition of concrete tanks. The following section describes some of these methods and their applications.

Structural Integrity and Strength

Advanced Ultrasonic Pulse Echo Tomography

Ultrasonic Pulse Echo (UPE) is an effective method in evaluating surface and sub-surface defects in reinforced concrete elements. The method involves the use of shear waves to identify sub-surface targets, such as voids, delamination, discontinuity, disintegration. The method can effectively be used to assess the quality and condition of grouting around the post tensioning cables, and identify if they are filled with grout or not.

Advantages

- Tests can be performed with single side access only

- No special need for plant shut down in most cases

- Test can provide A, B, and C Scans of the test area

Practical Considerations

- High resolution scan requires a relatively finer mesh, which will increase the amount of labour work, but it is highly recommended for areas of concern

- If there is a heavy coat on the surface, it has to be removed ahead of testing.

Rebound Hammer

Rebound Hammer test provides a practical and cost-effective solution for estimating in-place concrete strength. Recent developments in rebound hammers, and improved guidelines for estimating concrete strength can help structural engineers and condition assessment professionals in accurately classify concrete strength, and make data-informed decisions on the location of cores in a cost-effective framework.

Advantages

- Rapid and Cost-effective tool for comparative study of concrete quality and uniformity

- Can help identify the class of strength

Practical Considerations

- Surface should be prepared using an abrasive stone.

- Results can vary from one device to another, and one inspector to another.

- requires project-specific calibration to accurately estimate concrete strength.

Ultrasonic Pulse Velocity

Ultrasonic Pulse Velocity (UPV) can be used for quality control of new construction, as well as evaluation of structural integrity in existing facilities. The test setup can be customized to estimate the depth of cracks in walls and slabs.

The combination of rebound hammer test and ultrasonic test can provide information about the quality, homogeneity, uniformity of concrete. Moreover, the test results can be combined to predict the in-place strength of concrete.

Advantages

- Tests are rapid, and cost effective

- Can provide good estimate of concrete quality and strength.

Practical Considerations

- Test should be performed on concrete (paint and coat should be removed)

Impact-Echo

The Impact-Echo method has proven to be extremely useful in evaluating the thickness of concrete elements from one side (e.g. concrete tanks, tunnel lining, culvert wall, bridge abutment), determining the depth and location of subsurface defects (e.g. cracks, voids, honeycombing, debonding) within concrete, and estimating the depth of surface-opening cracks.

Advantages

- Estimate Thickness of Concrete Elements

- Locate Sub-Surface Defects

- Estimate the Crack Depth

Practical Considerations

- The impact-echo test is sensitive to the impactor size (contact time), and the distance of impact source and the sensor;

- Accurate estimation of P wave can sometimes be challenging.

Structural Detail

Ground Penetrating Radar

Ground Penetrating Radar (GPR) is a very useful technique for nondestructive evaluation of concrete. GPR uses pulsed electromagnetic waves to scan concrete. The test method provides an easy means to locate steel rebar, or any sub-surface targets (pipes, live conduits, etc.), and estimate the concrete cover thickness.

Advantages

- Very easy, and very rapid (if accesses are provided, and easy with no obstacles).

- Can identify location of rebar, as well as the depth of steel bars

- The test can be done in line scan or area scan. Area scan can be plotted in different slices (at each depth), providing information about details at each depth

Practical Considerations

- No information of corrosion, or mechanical properties

Durability Performance

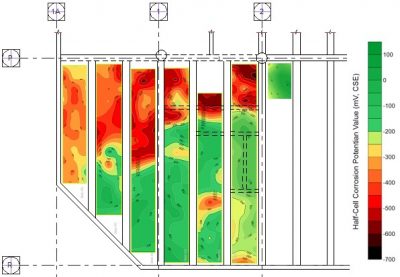

Half-Cell Corrosion Potential Mapping

Half-Cell Corrosion Potential Test is an effective electrochemical test procedure that is widely used among condition assessment engineers for evaluation of corrosion. The test can provide information about the likelihood of having active corrosion.

If corrosion is involved, the test provides a cost effective screening tool for identifying the locations and areas with higher probability of corrosion.

Advantages

- When performed properly, the test can provide reliable maps of corrosion activity.

Practical considerations

- The test should be done in one concrete. Coating should be removed ahead of testing,

- If there is a post tensioning duct, the test does not provide information on the cables passing inside.

Surface Electrical Resistivity

The use of electrical resistivity method for quality control and evaluation of concrete durability is becoming very popular among scholars and engineers. The measurement of electrical resistivity of concrete provides useful information about the microstructure of concrete material. The test procedure has since been standardized by AASHTO TP 95. This method is adapted by several Department of Transportation (DOTs) to replace the labour-intensive and time-consuming methods such as the ASTM C 1202, “Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration”, generally known as the Rapid Chloride Peremeabiliy Test (RCPT).

Sariah Meagle

I think non-destructive testing might help in the identification of defects as you said since the tanks look mostly the same to me. Since you mentioned that there are different methods that can be used by laboratories, it might be a good idea to test at least one method out. We might try out half-cell corrosion mapping because it's a widely used test procedure as you listed and we find it convenient but we'll see how things will go first.

Ultrasonic Pulse Echo Tomography for Concrete | FPrimeC Solutions Inc.

[…] Ultrasonic Pulse Echo Testing in Concrete Tanks - Paper Mill, Gatineau, QC Example of UPE tomography maps and Thickness Measurements (Tests on a concrete slab in laboratory conition) […]

Ella Starr

How helpful that you talk about how the Impact-Echo method is useful in evaluating the thickness of concrete. I want to start a new business this summer. For this, I will find a good concrete water tank in my area actually.

Adam Golightly

My uncle has been thinking about getting the right kind of concrete tanks under his background in order to be better. He would really like to get some help from a professional to make sure that it can be installed properly. I liked what you said about how they can prevent any concrete weakness with the right kind of quality with a better class of strength.

Shailendra Bhavsar

One of the point came from Audit is to do integrity test of the ETP RCC tanks?

which test will be need for the compliance of this point