Scope

FPrimeC Solutions Inc. was engaged by a steel company in Hamilton, Ontario to perform drone visual inspection, and non-destructive evaluation (NDE) on a Q-deck composite concrete slab. The structural system of the concrete floor was Q-deck consisting of composite metal decking and concrete slab. The objective of this investigation was to determine the present condition of the concrete slab and metal deck, as well as evaluate the presence of corrosion within the structure.

Elios 2 Drone for Inspection of Metal Deck from underside

Drone inspection was performed by Elios 2 drone was used to collect footage of the present condition of the metal deck below the q-deck slab. As the floor structure in this project contains both a Q-deck in addition to a composite concrete slab, the ability to obtain footage of the metal deck was very necessary to be able to comment on the overall condition of the structure.

Non-destructive Evaluation of Concrete

A combination of Ultrasonic Pulse Velocity (UPV), and Rebound (Schmidt) Hammer tests was used to assess the overall quality of concrete materials. Ultrasonic Pulse Velocity (UPV) was used to verify the pulse velocity in concrete, and assess concrete quality and uniformity at select areas. Rebound Hammer test was used to assess uniformity and surface hardness of the concrete.

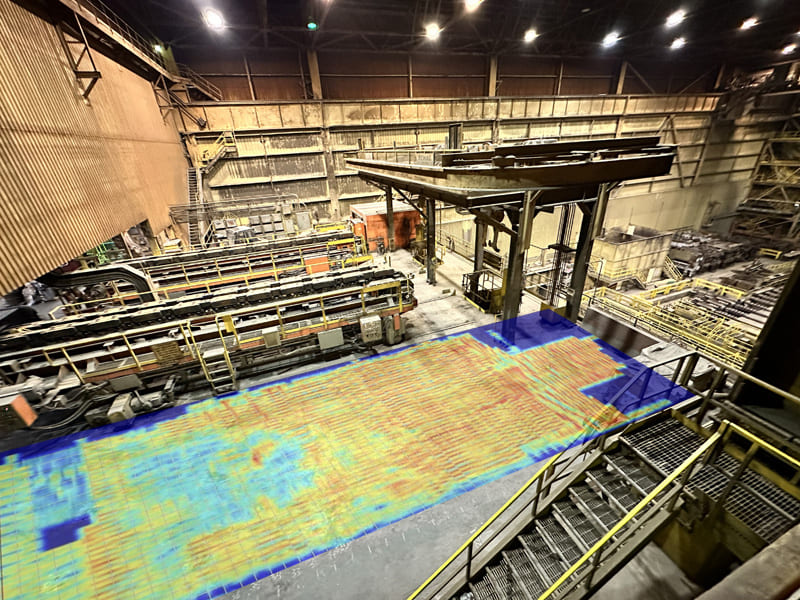

Corrosion Inspection Using GPR

Ground Penetrating Radar (GPR) was used to acquire the location of rebar, and estimate the presence of corrosion. The combination of these tests allow us to determine which parts of the structure are more compromised then others, and provide asset holders the flexibility in staggering repair times and costs by choosing which sections to repair based on their level of criticalness.