Scope

FPrimeC was hired by the Town of Oakville to perform an intelligent digital inspection and non-destructive evaluation of concrete at a parking structure in downtown Oakville, ON.

The parking structure had 4 levels including a basement and a roof level. The structure consisted of precast concrete walls, columns, and beams. The main flooring system consisted of prestressed concrete double tee beams connected using steel connectors. Several joints showed signs of deteriorated seals, where moisture penetration had resulted in localized corrosion of steel bars and shear connectors. The corrosion was mainly across the edges of the double tee beams. The main objective of the project was to assess the condition of the existing concrete structure using smart digital inspection, non-destructive testing and evaluation, and validation through intrusive tests.

1- Digital Inspection of Parking Structure

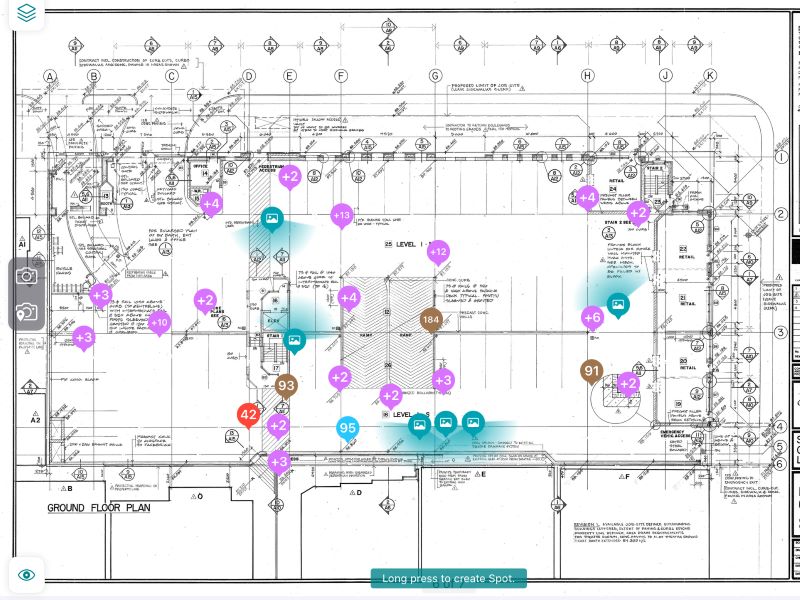

Due to the relatively large area and complexity of the parking structure, FPrimeC used the “INSPECT” digital inspection solution which is a comprehensive, cloud-connected software platform that seamlessly integrates into inspection workflow – facilitating data collection in the field and reporting in a fully digital, customizable and collaborative way. This enabled FPrimeC engineers with location-based capturing, in which all visual inspection results can be pinned to their precise location on the structural drawing plans, reducing the inspection and reporting timeline.

The platform enabled FPrimeC to seamlessly integrate the results of non-destructive testing and intrusive tests into the existing drawings.

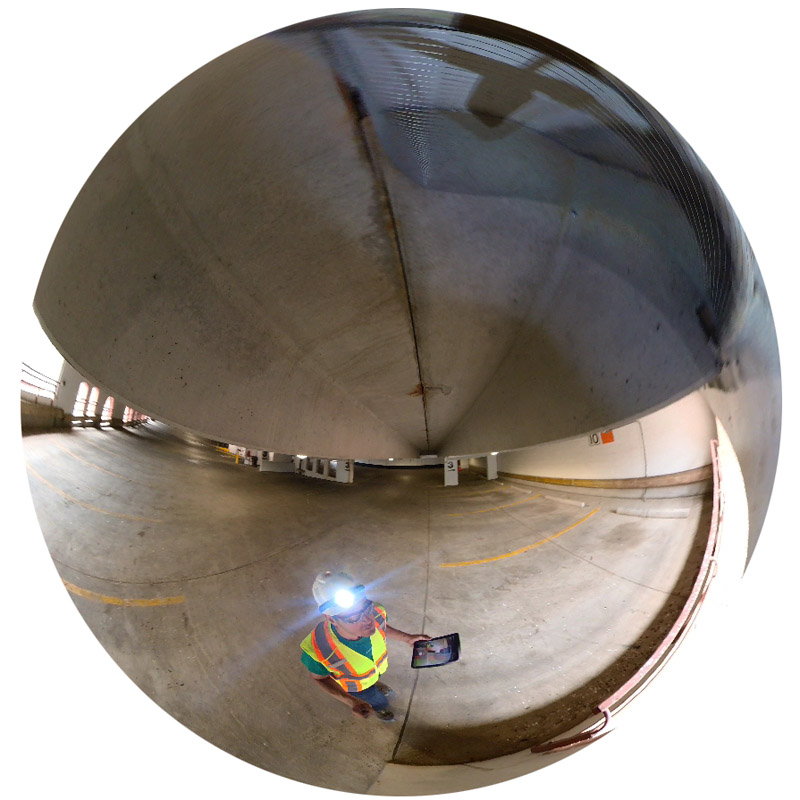

2- 360° Capture for Parking Structure

As part of our digital inspection of the parking structure, 360° Video Capture was used for rapid, accurate and cost-effective inspection of key structural components. 360 Capture reduces the inspection timeline and provides an invaluable archive for engineers’ review in the office. The video capture can be further enhanced when combined with the reality capture feature of the Inspect platform. In this project, Insta360 camera was used for 360° Capture of structural inspection. The wireless feature and a telescopic arm help eliminate the need for work at height platform and provides a real-time close up view of defective areas that are hard to reach.

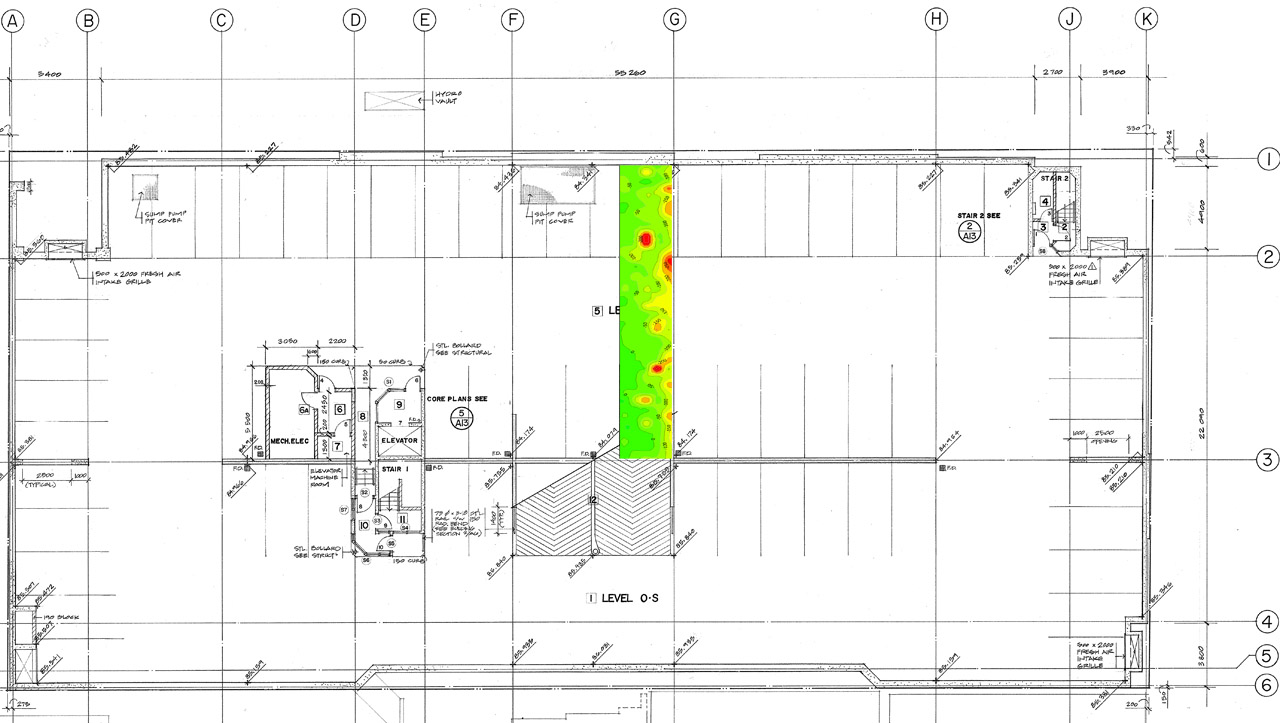

3- Non-Destructive Testing and Evaluation of Parking Structure

Non-destructive Testing and Evaluation (NDT/NDE) was used to evaluate the current condition of concrete double tee beams. Half-Cell Corrosion Potential Mapping (HCP) was used to study the likelihood of active corrosion in concrete beams. The Ultrasonic Pulse Velocity (UPV) was used to evaluate the condition of concrete at the stem of beams. Half-Cell maps help the client in better evaluate the maintenance needs and help identify areas with a higher chance of corrosion activity.

4- Validation through Intrusive Assessment

Findings and observations were validated by taking concrete core samples and saw cuts. The condition of steel bars and connectors was assessed.