Scope

FPrimeC Solutions Inc. was hired by a steel company in Hamilton, Ontario to perform digital visual inspection, and non-destructive evaluation (NDE) of the concrete settling basin structure. The exterior walls, as well as the soffit of the settling basin showed sign of cracking, and potential leakage. Soffit areas also showed sign of moderate delamination. The main objective of the project was to evaluate the present condition of the concrete settling basin, evaluate maintenance needs, and provide concrete repair solutions for existing deficiencies.

Digital Inspection of Settling Basin Structure

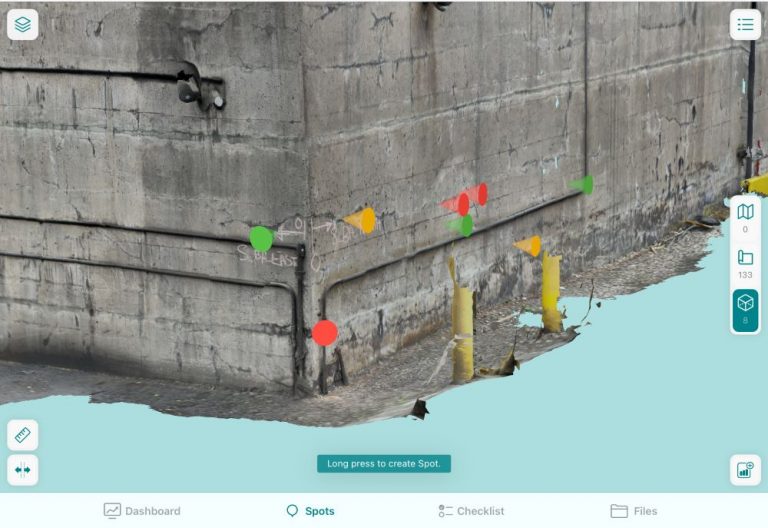

Due to the relatively large area and complexity of the settling basin structure, FPrimeC used the “INSPECT” digital inspection solution which is a comprehensive, cloud-connected software platform that seamlessly integrates into inspection workflow – facilitating data collection in the field and reporting in a fully digital, customizable and collaborative way. This enabled FPrimeC engineers with location-based inspection of the asset, identifying existing deficiencies over PDF files, and to assign sensor data to the test locations.

FPrimeC engineers were able to pin the visual observations, including 360 photo captures, as well as NDT/NDE results (i.e. Rebound hammer results, and Ultrasonic Pulse Velocity results) for each and every component (walls, columns, soffit) over the existing structural drawings right on spot. This allows for significantly lower inspection timeline, an enhanced data quality, accuracy, and tractability, and reducing the reporting timeline.

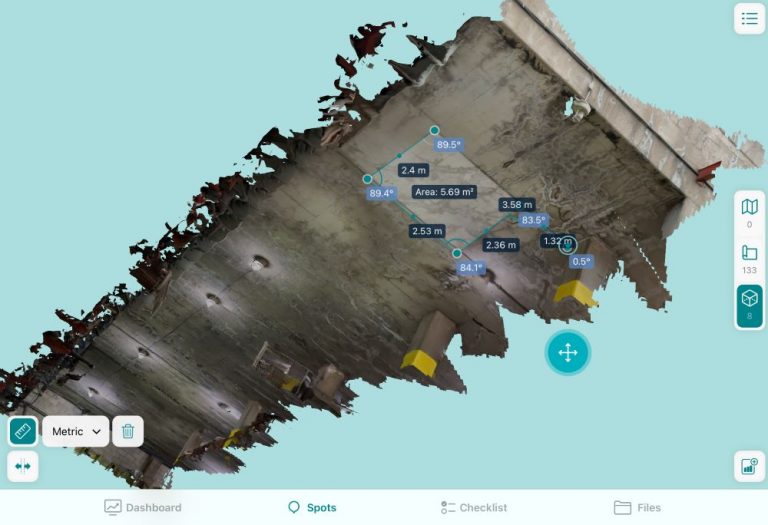

3D Models using Lidar was developed at component level, and existing deficiencies, along with NDT results were pinned to the drawings.

360 Capture for Inspection of Settling Basin

360 Capture was used for rapid, accurate and cost-effective inspection of key structural components. 360 Capture reduces the inspection timeline and provides an invaluable archive for engineers’ review in the office. The video capture can be further enhanced when combined with the reality capture feature of the Inspect platform. In this project, Insta360 camera was used for 360 Capture of structural inspection. The wireless feature and a telescopic arm help eliminate the need for work at height platform and provides a real-time close up view of defective areas that are hard to reach.

Non-destructive Evaluation of Settling Basin Structure

A combination of Ultrasonic Pulse Velocity (UPV), and Rebound (Schmidt) Hammer tests was used to assess quality and uniformity of concrete. Ultrasonic Pulse Velocity (UPV) was used to verify the pulse velocity in concrete, and assess concrete quality and uniformity at select areas. Rebound Hammer test was used to assess uniformity and surface hardness of the concrete. Moreover, a customized UPV setup was used to provide preliminary estimates of the Crack Depths.