Dam Safety

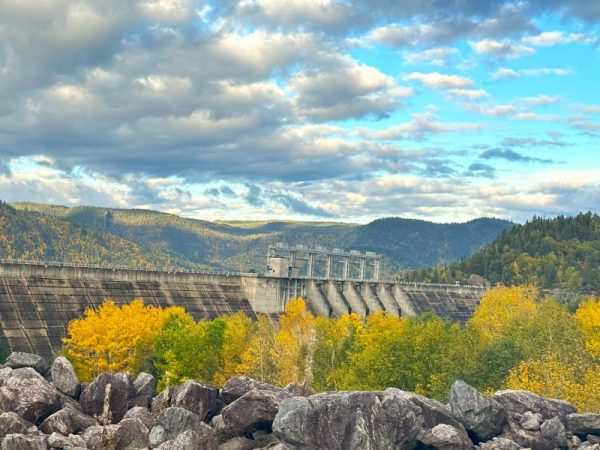

Nondestructive evaluation of concrete dams is gaining interest among dam safety assessment professionals. Nondestructive testing can help engineers evaluate the soil-dam interface, as well the overall condition of key structural elements such as the spillways, and the crown bridge. FPrimeC was engaged by the client to perform comprehensive multi-technology nondestructive testing and evaluation over the crown bridge of Outardes-2 and Bersimis-2 dams in northern Quebec, Canada.

Nondestructive Evaluation of Concrete Dam

FPrimeC Approach: A Multi-NDT Solution

A multi-technology approach was adapted for the Nondestructive evaluation of concrete dams in Quebec. Several reasons are behind opting for a multi-technology NDT/NDE approach:

- Multi-technology method allow for a thorough evaluation of the specified test areas under a variety of methods, so that the client could critically compare the data presented from one method to another.

- Although NDTs are extremely effective tools to detect anomalies, defects and other structural issues in concrete, each method has its own physical and practical limitations. A multi-technology approach combines the strength of each method and helps clients get a clear picture of anomalies and structural details.

- Multi-technology nondestructive evaluation minimizes the risk of false-positive and false-negative results.

On each dam structure, three test areas were chosen for a comprehensive investigation. A multi-technology NDT/NDE approach; including five NDT methods, was selected for this project:

- Concrete Visual inspection and Sounding based on ASTM D4580

- Ground Penetrating Radar (GPR) Scan based on ASTM D6087

- Ultrasonic Pulse Echo Tomography based on ACI 228.2R-13 article 3.2.2

- Impulse-Response method based on ASTM C1740

Concrete Scan using - Spectral Analysis of Surface Waves (SASW) method based on ACI228.2R article 3.2.4.techn

Visual Inspection and Sounding

Visual inspection and sounding were performed to evaluate the visual condition and quality of concrete elements in each test area, and identify potential sub-surface anomalies such as delamination and spalling. For sounding, a rotary percussive device was rolled over the concrete surface. Signs of existing patch repairs, and spalling were identified by FPrimeC engineers. Dull or hollow sounds created from the rotary percussion device striking the surface, indicated the areas prone to delamination and were marked.

Ground Penetrating Radar

Ground Penetrating Radar (GPR) is a non-intrusive test method for scanning and imaging subsurface defects, voids, and objects (i.e., steel reinforcement, metal objects, etc.). GPR scans were taken across longitudinal and transverse line spaced at 0.3m apart. The line scans were amalgamated together through a software program to generate slice view images of the concrete deck at various depths into the concrete. GPR scans were studied to identify potential sub-surface anomalies in the concrete elements, including rebar corrosion, delamination, and moisture. The sub-surface targets in the shallow depth (0 to 200 mm) with characteristics of voids/delamination were marked.

Ultrasonic Pulse Echo

The Ultrasonic Pulse-Echo (UPE) method was used for thickness measurements, flaw detection, and evaluation of the integrity of concrete. The concept behind this method relies on the propagation of stress waves through materials. The stress waves propagate into the test object and are reflected by flaws or interfaces. The device used for this project has a theoretical scan depth of up to 450 mm. A single UPE reading was taken at each of the gridline cross hairs. Afterwards in the office, the scans were analyzed then classified into three groups to form a Tricolor heat map for data presentation. The heat map represents the potential anomalies based on the project-specific criteria.

Impulse-Response

The Impulse-Response method offers a rapid, cost-effective and non-destructive way to assess thin concrete plates such as walls and slabs. The test provides valuable information on the likelihood of defects which helps with the quality assurance of concrete repair and rehabilitation. In this method, average mobility is determined for a frequency range of 100 Hz to 800 Hz. Assuming that the concrete thickness remains the same over the test area, the variations in the calculated average mobility across the test areas can be used to identify the areas with potential anomalies. A tri-color map scheme was adapted for the representation, based on the following criteria:

Spectral Analysis of Surface Waves (SASW)

The Spectral Analysis of Surface Waves (SASW) method uses the dispersive characteristics of surface waves to determine the variation of shear wave velocity at different depths across the test area. The technique utilizes the propagation of stress waves (shear waves) generated by a hammer impact to analyze the mechanical properties of concrete, evaluate the integrity and uniformity, and identify potential defects. The shear wave was determined at three (3) different depths; 0.2m, 0.4m and 0.6m. Certain assumptions and equations were used to estimate the compression wave speed in concrete.

Concluding Thoughts

FPrimeC partnered with the prime consultant to perform comprehensive condition assessment of the crown bridge in two concrete dam structures in Quebec.

This assessment provided a wealth of information that is available to any maintenance managers. This information can help with identifying the location and extent of subsurface anomalies, and prioritize repair and maintenance needs.