Scope

FPrimeC was hired by to perform visual inspection and non-destructive testing of a Steel Tank in a Hospital, in Lindsay. ON. The Steel Tank had signs of earlier corrosion (repaired) and existing repair. Potential leaks were observed at the intersection of valves and the steel shell. Digital inspection was proposed to record the condition of the interior and exterior of the tank shell. Non-destructive Testing involved Magnetic Particle Examination (MT) of steel shell on or around the welds, as well as Ultrasonic (UT) thickness evaluation of the shell.

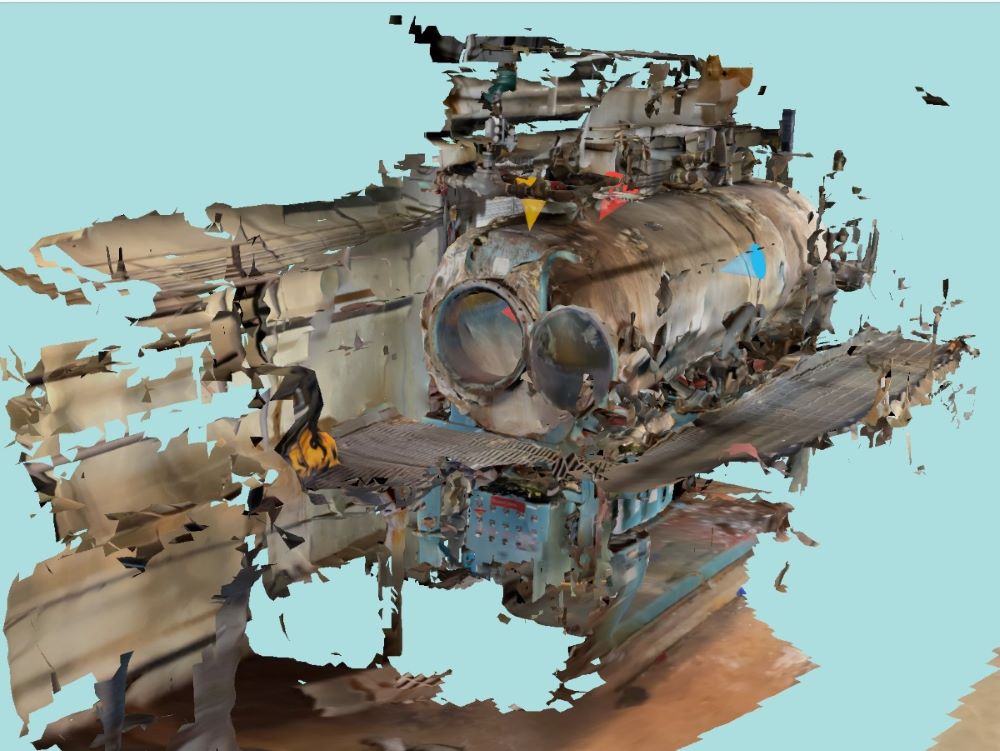

1- Digital Inspection of Steel Tanks

FPrimeC digital inspection solution to capture the “As-Is” condition of the asset. Lidar and 360 Video Capture were used to record all existing deficiencies in the Tank, and across the welds. This enabled FPrimeC engineers with location-based inspection, in which all visual inspection results can be pinned to their precise location on the 3D structural model developed by Lidar, reducing the inspection and reporting timeline.

2- Non-Destructive Testing of Steel Tanks

Two NDT Methods were deployed in this investigation:

A) Magnetic Particle examination was performed (MT-1 procedure) for detecting surface and shallow subsurface discontinuities on or around the welds as per CSA guidelines, using a certified inspector.

B) Longitudinal Ultrasonic Testing was performed for evaluating internal defects within the steel shell, and to estimate the thickness at several locations.

The combination of two methods were used to identify the location and extent of potential corrosion in the tank (reduction in steel section).