Condition Assessment of Wastewater Treatment Plant

A Non-Destructive Approach

Water and Wastewater Treatment Plants operate in some of the most aggressive service environments. Concrete structures in these plants are subjected to a constant dual threat: chemical attack from the processing fluids and environmental degradation from freeze-thaw cycles. Ensuring the longevity of these assets is critical to avoiding costly unplanned shutdowns and environmental compliance issues.

FPrimeC Solutions was engaged to perform a multi-phase Condition Assessment of Wastewater Treatment Plant in Ontario. Concrete walls of five critical process tanks (Primary and Secondary Clarifiers and a Chlorine Contact Tank) of the wastewater pollution control plant were thoroughly examined. The objective was to determine the root cause of visible deterioration and provide a data-driven roadmap for service life extension.

The Challenge

The client had identified visual anomalies on the tank walls that raised concerns about long-term durability performance and structural integrity of the concrete tanks.

-

Map Cracking: The upper sections of the walls (above the waterline) exhibited extensive map cracking.

-

Surface Erosion: The lower sections (submerged zones) showed significant surface roughness and loss of cement paste.

The engineering objective of the condition assessment of wastewater treatment plant was to determine if these defects were superficial or symptomatic of deeper durability issues such as Alkali-Silica Reaction (ASR) or Biogenic Sulfuric Acid Attack. The client required a quantitative evaluation to make informed decisions regarding capital repair budgets.

The Solution: A Forensic Engineering Approach

FPrimeC deployed a holistic testing strategy combining Non-Destructive Testing (NDT) for broad coverage with intrusive forensic sampling for material characterization.

1. Non-Destructive Testing and Evaluation (NDT-E)

We utilized a suite of advanced NDT-E methods for effective condition assessment of concrete quality without damaging the structure:

-

Ultrasonic Pulse Echo (UPE): Used to assess the internal consistency of the walls and verify wall thickness and back-wall reflection, ensuring no massive internal voids existed.

-

Ultrasonic Pulse Velocity (UPV): Deployed to estimate the depth of surface cracks. By measuring transit time, we could determine if the visible map cracking was penetrating deep into the rebar zone or remaining superficial.

-

Rebound Hammer: Used to map surface hardness and uniformity across different elevations of the tank walls.

2. Intrusive Sampling & Forensic Petrography

To diagnose the specific chemical mechanisms at play, the team extracted concrete cores for laboratory analysis:

-

Rapid Chloride Permeability Testing (RCPT): To determine how easily aggressive ions could penetrate the concrete matrix.

-

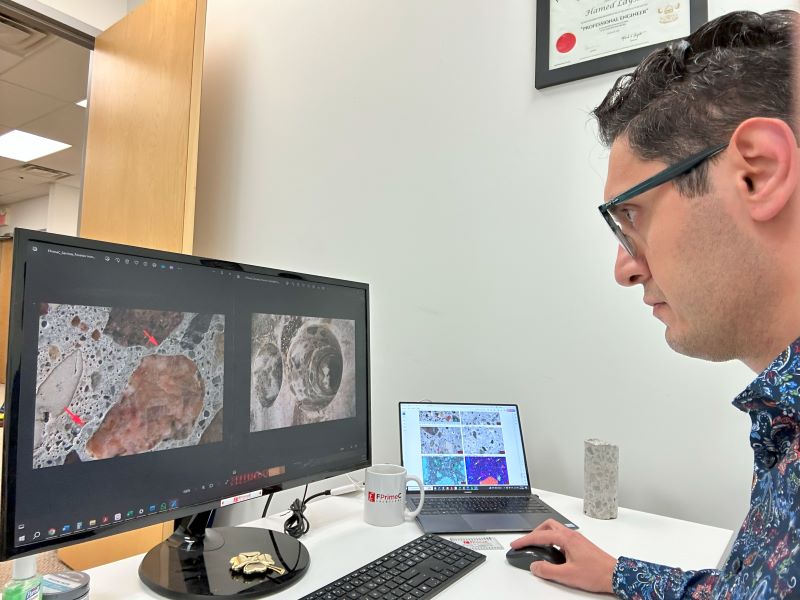

Petrographic Examination: The most critical step. High-powered microscopy was used to analyze the microstructure of the concrete, identify reaction products (like ASR gel), and evaluate the paste-aggregate bond.

-

Test Pits: Selective demolition was performed to visually inspect the condition of the embedded steel reinforcement.

Value Delivered & Path Forward

By moving beyond simple visual inspection, FPrimeC provided the client with a precise diagnosis that saved unnecessary full-depth rehabilitation costs.

Strategic Recommendations:

-

Crack Injection: To restore monolithic behavior and stop moisture ingress, cracks wider than 0.15mm were recommended for low-viscosity resin injection.

-

ASR Mitigation: Application of Lithium-Nitrate based coatings was recommended to slow the expansion rate of the ASR.

-

Chemical Resistance: For the submerged areas, cleaning and applying antimicrobial protective coatings were prescribed to halt the biogenic acid attack.

Conclusion

This project exemplifies how Advanced Non-Destructive Testing for condition assessment of wastewater treatment plant can transform uncertainty into accurate and reliable insight for enhanced reliability assessment. Instead of guessing the cause of the cracking, the client now has definitive proof of the deterioration mechanisms and a clear, cost-effective maintenance plan to extend the service life of these critical assets by decades.