Deterioration of reinforced concrete structures can happen for a number of reasons. Physical and Chemical processes can impact durability and structural performance of the concrete. Defects in design, materials, workmanship, curing and maintenance can all impact the service life, safety and reliability of an element. In this article, we will review some of the most common types of deterioration mechanisms in concrete.

Why concrete structures fail? Concrete has long been known as a reliable construction material, but deficiencies in material selection, detailing, and design can affect the service life of Concrete. Deterioration of concrete structures can become a challenge for the owners of these structures. It is important to identify these defects on time, and plan appropriate repair strategies. In this article, we will review some of the most famous deterioration mechanisms. In doing so, we have focused on the Ontario Structure Inspection Manual (OSIM, 2008). In addition, the review of the following two documents is highly recommended in learning defects and deterioration of concrete (Reference 1 and Reference 2).

Deterioration of Concrete

Before we begin this review, It is good to review the definition of the following two terms according to the OSIM (2008):

- Defect: An identifiable, unwanted condition that was not part of the original intent of design.

- Deterioration: A Defect that has occurred over a period of time

Different defects can be involved in the deterioration of concrete. The following review provides a brief summary on the most common defects observed in the existing structures. Normally, one or a number of these defects can be seen in structures; therefore, it is necessary to identify them properly. One needs to understand these different defects properly in order to get more realistic evaluation of the structure.

1- SCALING

What is it?

Scaling is referred to the loss of the surface portion of concrete (or mortar) as a result of the freezing and thawing (OSIM, 2008). It is a physical action that usually leaves the aggregates clearly exposed. (PCA, 2001).

How it happens?

Scaling happens when the hydraulic pressure from water freezing within concrete exceeds the tensile strength of concrete. Scaling is more common in non-air-entrained concrete, but can also occur in air-entrained concrete in the fully saturated condition.

2- DISINTEGRATION

What is it?

Disintegration is the physical deterioration (such as scaling) or breaking down of the concrete into small fragments or particles.

How it happens?

It usually starts in the form of scaling. It may be also caused by de-icing chemicals, sulphates, chlorides or by frost action.

3- EROSION

What is it?

Erosion is the deterioration of concrete surface as a result of particles in moving water scrubbing the surface.

How it happens?

When concrete surface is exposed to the water-borne sand and gravel, the surface gets deteriorated by particles scrubbing against the surfaces. Flowing ice particles can also cause the problem. It is an indicator of poor durability of concrete for that specific exposure.

4- CORROSION OF REINFORCEMENT

What is it?

Corrosion is the deterioration of steel reinforcement in concrete. Corrosion can be induced by chloride or carbonation. The corrosion can result in cracking in the concrete cover, delamination in concrete decks, etc.

How it happens?

When the concentration of chloride ions above the surface of reinforcement reaches the threshold limit (which is the amount required to break down the passive film) corrosion begins. The volume of resulting material (rust) is 6-7 times, which increases the stress around the rebar, and causes fracture and cracking. The cracks extend to the surface of concrete over time; that is when we can visually see the sign of rust over the surface of concrete.

5- DELAMINATION

What is it?

“Delamination is defined as a discontinuity of the surface concrete which is substantially separated but not completely detached from concrete below or above it.” (OSIM, 2008). Delamination is often identified by the hollow sound by tapping or chain dragging of concrete surface.

How it happens?

The corrosion of reinforcement and subsequent cracking of the cover can cause delamination. When the rebar have small spacing, the cracking extends in the plane of the reinforcement parallel to the exterior surface of the concrete.

6- SPALLING

What is it?

Spalling can be considered an extended delamination. In fact, when the delamination continues, the concrete fragments detach from a larger concrete mass.

How it happens?

If delamination is not repaired on time, the progress of damages as a result of external loads, corrosion, and freezing and thawing can break off the delaminated pieces.

7- ALKALI-AGGREGATE REACTIONS

What is it?

It is the internal cracking of concrete mass as a result of a chemical reaction between alkalis in the cement and silica in the aggregates. The AAR/ASR cracking are very famous for their crack patterns.

How it happens?

The alkalis in the cement can react with the active silica in the aggregates to form a swelling gel. When this gel absorbs water, it expands, and applies pressure to surrounding environment which makes the concrete crack.

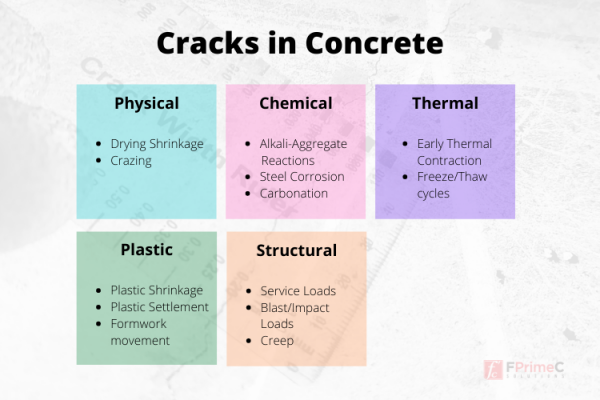

8- CRACKING OF CONCRETE

What is it?

A crack is a linear fracture in concrete which extends partly or completely through the member.

How it happens?

Some people believe that concrete is born with cracks; that its ingredients, and how it is produced – from the batching plant to pouring, setting, and curing – is influenced by so many factors that cracking of concrete does not come as a big surprise; and to a great extent, that might be true. Cracking of concrete can happen in different stages: It can happen before hardening of concrete, and it can happen in an old concrete structure:

Before Hardening

+ Settlement within concrete mass

+ Plastic shrinkage

After Hardening

+ Drying shrinkage

+ Thermal contraction

+ Sub-grade settlement

MS Ahamed Mihraj

Hydraulic concrete structures in water subjected to fluid velocity > 3.2 m/s need special mix design & additional coatings to prevent surface cement loss.

Also rapid hardening cement if used without guideline may causes concrete cracking due to internal chemical reactions of components. Best use normal Portland cement for concrete.

Yemi Ariye

Good reminder and useful stuff for professionals

Gordon Chirgwin

The concrete can also be designed to be resistant by using very durable concretes, such as high Silica Fume content concretes. Refer to the US bureau of Reclamation work on spillways for further information.

Rakesh Chopra

It is a good informative article on the fundamentals and, after the incident has taken place. May be adding, how and what to regularly inspect and record, along with instant maintenance techniques if added, make it practical in the field.

Naeem Lodhi

Good technical information. It would be worthwhile to evaluate that what type of deterioration is considered to be a major structural damage ? Spalling, specially in case of slender columns ? Cracks wide enough to expose steel bars ? Etc. Also important is the alignment(vertical, horizontal or diagonal) and location of cracks in load bearing and bending moment resistant members. These will indicate design or workmanship deficiencies other than the reasons mentioned above . Regards .

Naeem Lodhi

Chris Godfrey

Concrete waterproofing prevents or greatly reduces damage from all these causes. It is often ignored in new construction because the damage is down the road and some ones maintainance budget can cover it but for the facilities owner this is penny wise and pound foolish thinking. Waterproofing at the time of new construction can save many times its cost over time. Basecrete a polymodified concrete is a cost effective solution.

MS Ahamed Mihraj

Hello Chris,

Concrete Water proofing may be sufficient for most of the structures but sewer manholes /treatment plants require special coats such as epoxy based painting two to three coats for raw sewer attack on concrete considered as extreme environment.

Design life of these structures are less than 20 years.

Charles Kemp

If you get more aggregate on these areas that are deteriorating, it could make the place hold a little bit longer. I think you should really make sure that the aggregates don't get ruined because you will need them. It might also help to have something to block out water so it doesn't get worse.

Girma

How about the remedial measures?

Jim Gilliland

Reasons for concrete cracking - need to also include basic/autogeneous shrinkage, and heat of hydration effects during construction.

Terry Stransky

This is very basic information , almost too basic for experienced concrete practitioners. As a concrete petrographer, I have seen all of these and additional deterioration mechanisms. Nevertheless, a good brief introduction to common concrete problems.

Mic mlcm

Good reminder for us practitioners. Hope to hear more from you.

Avinash

If Spalling occurs in roof slab, how to repair it?

Cliffort Vogelland

Very important article for concrete world! Thank you.

A. Kameswara Rao

Very good info. Deformation or cracks in concrete has to be attended on priority otherwise the important structure will collapse.

Gil Patricio Ganaden

Good info to start discussing concrete repair. We love to hear latest concrete repair approach.

Sharad deshmukh

What will be the implication on such detoriation of concrete has been manage to repair ... in connection with its actual strength st the time of detoriated and after repaired on . Will it affect on capacity of overall structural strength . Upto what extend of % we can suggest Coustmer to go far repair one rather than rebuild or demilition

Luis Humberto Mantilla

Antes de fundir (vaciar el concreto) los elementos estructurales, es muy importante verificar el recubrimiento mínimo requerido o especificado por el calculista. Tambien es importante en el diseño, verificar la cantidad de varillas del refuerzo que realmente caben en la seccion, control del indice de profundidad de la grieta

4 Methods of Condition Survey for Bridge Decks | FPrimeC Solutions

[…] Concrete Decks suffer from various deterioration mechanisms; i.e. freezing and thawing, corrosion. The most significant consequence is the delamination of […]

Dennis Hrapeck

Usually the most effective way to prevent most of the problems with concrete is to use aggregates containing the ideal amounts of calcium carbonate and silicates with good freeze- thaw properties to start with. Water content must also be closely monitored. There are so many things that can affect concrete adversely after pouring that it only makes sense to control the factors you have control over during production.

Abdelrahman Armouti

All known mechanisms of concrete corrosion & deterioration (and they are 11 mechanisms) have one common denominator, and that is WATER. If Concrete doesn't absorb water, NON of those mechanisms can happen.

The addition of an HPI admixture (Caltite) to the Concrete mix, makes it Hydrophobic, i.e: (water-repellent concrete) preventing the root cause of all deterioration in concrete, resulting in durable & sustainable concrete.

Hasan S Akhtar

Durability of the concrete can be improved by adding fiber. Most economical and easiest to use is polypropylene fiber.

Secondly, fly ash can reduce the non durable binder in concrete that make the concrete permeable and susceptible to chloride attack.

Gordon Chirgwin

You should really have included carbonation as a cause in corrosion, as well as just plain old lack of cover!

Non-Destructive Testing of Concrete Tanks | FPrimeC Solutions

[…] and monitoring of concrete tanks, and NDT methods than can be used to address these challenges. Deterioration of concrete can occur over time. Environmental conditions such as weather (extreme hot/cold) can cause […]

How to Evaluate Bridge Abutments? | FPrimeC Solutions

[…] mainly because seismic provisions were only adapted in design codes in the 1970's. Moreover, deterioration of concrete over the service life of the structure could negatively impact the durability and structural […]

Concrete Imaging and Scanning | FPrimeC Solutions

[…] Scanning can be used to reveal sub-surface deficiencies such as voids, delamination, poor quality patches. Moreover, the NDT methods can be used to locate […]

Gerty Gift

Thank you for explaining what spalling is. My friend mentioned the word in passing, but I couldn't figure out in what context it was. It definitely made that conversation make more sense and made me feel more informed for what to look out for on various concrete structures.

times diary

Thanks for sharing it's very helpful for me.

zubair

Very informative article Thank you for sharing.

bablu

good post, thanks to admin

Sorkari Chakri

this post has been of great help to me. thanks

Govt Job Circular

Nice post. Thank you for sharing it.

Expanded Metal

This is a very informative blog, thanks for sharing about deterioration of concrete structures . It will help a lot; these types of content should get appreciated. I will bookmark your site; I hope to read more such informative contents in future… great post!! Found an another website Dukeswiremesh.com it has lots of valuable information for everyone.

Milla Tietkens

Thanks for writing this great article for us. I have gained good stuff from this website. Looking forward to your next article. I am happy to share this post to my friends. Keep it up.

Jack Brown

I have enjoyed reading this report about rendering services. Really it is more useful and also helpful. I am very glad to go through this kind of informative article. Thanks for sharing a nice blog.

Alana Wilshire

Really, it is more helpful for rendering work. I am very glad to go through your wonderful article. Thanks for sharing a nice article.

Cameron Baile

Very thankful for this wonderful article, it seem like it will really help with what I need to get done. Thank you very much for the post!

Taylor Hicken

I do agree when you shared that the deterioration of concrete structures is one of the challenges for the owners of these structures. It is important to come out with a solution to ensure that these structures will look great again. I would like to think if a company has a deteriorated concrete structure that has no chance of being fixed, it should consider demolish it and rebuild it again.