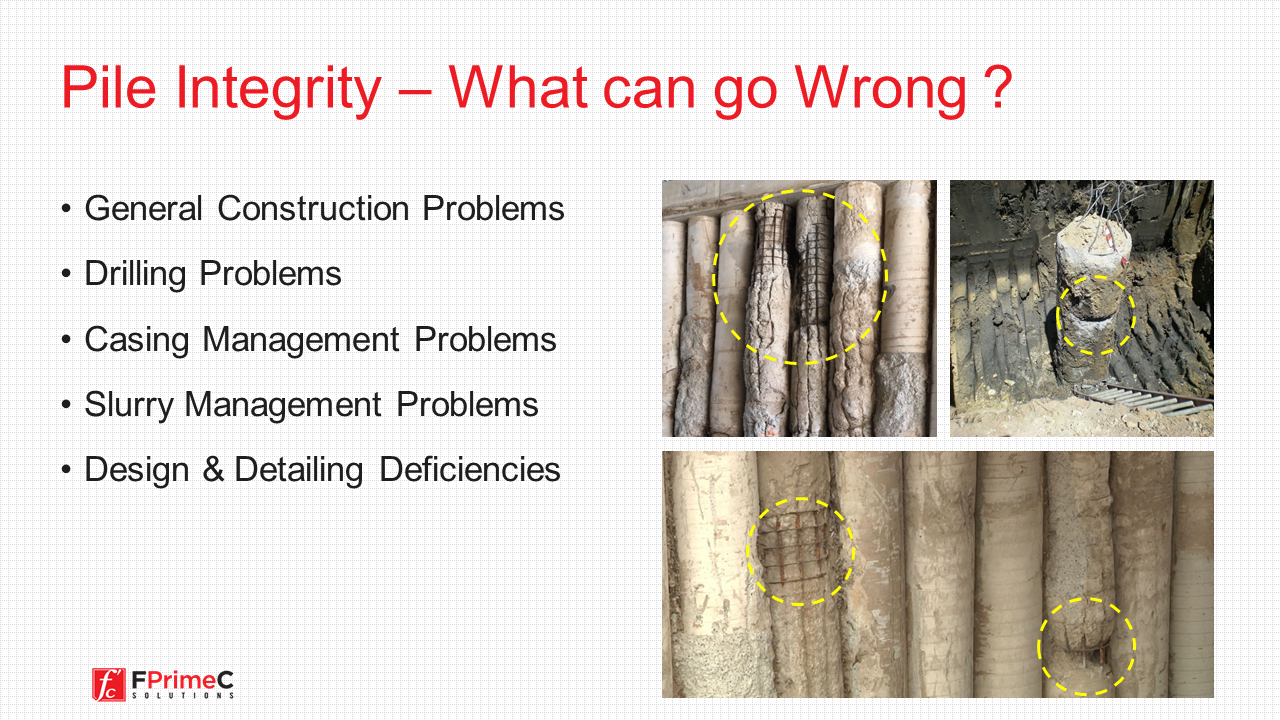

Construction and installation of concrete pilesand deep foundations is a challenging task. Problems may occur during the process, which in turn results in defects or anomalies such as: pile formation problems, concrete faults, and reinforcement installation issues. The resulting defects can negatively impact the durability and mechanical performance of the pile.Pile Integrity Tests are a group of non-destructive test methods that are used by geotechnical engineers and contractors to for quality control and quality assurance of deep foundations and piles. This article describes some of the most important NDT methods for evaluating pile integrity

What is Pile Integrity ?

Concrete piles and drilled shafts are an important category of foundations. Despite their relatively high cost, they become necessary when we want to transfer the loads of a a heavy superstructure (bridge, high rise building, etc.) to the lower layers of soil. In general, Pile Integrity refers to certain characteristics of deep foundations and piles such as:

- Physical Dimensions of Pile (Length or Cross-Section);

- Continuity of Pile (presence of Voids or Major Cracks); and

- Consistency of the Pile Material.

The special geometry of these elements (such as their length, diameter, and presence of steel cage) make certain challenges during the construction process:

- Pile Formation Issues

- Concrete Placement Issues

- Steel Cage Installation Issues

These issues may result in defects such as discontinuity (cracks, voids), or sudden change of cross section (bulging, necking) in pile elements, refereed to as Pile Integrity.

Since pile elements are generally buried under ground, the Quality Control and Quality Assurance of these elements becomes a challenging issue. Different intrusive and non-intrusive methods have been developed over the past decades to help engineers with easy, reliable and cost-effective methods for the evaluation of quality and consistency in these elements. Most of the time, the pile head is the only accessible area for inspection and testing.

What are Pile Integrity Tests ?

According to the ASTM D5882, Pile Integrity Test refers to qualitative evaluation of the physical dimensions, continuity of a pile, and consistency of the pile material.

Several methods have been developed over the past few decades in order to evaluate the integrity of piles. The selection of test method depends on many parameters, including (but not limited to):

- Pile Dimensions (cross section, depth)

- Pile Type

- Strata / Soil Condition

As we discussed in the previous sections, access to pile element is often limited to the pile head area. Therefore the test either have to performed on pile head, or certain features need to be implemented during pile construction. In this article, we will present the most common NDT methods for evaluation of pile integrity:

- Low-Strain Pile Integrity Test

- Crosshole Sonic Logging

- Thermal Integrity Test

Each testing method has certain advantages and limitations. The following sections will briefly present and discuss these test methods.

1- Low Strain Pile Integrity Test

Pile Integrity Test (PIT), or “low strain impact integrity testing of deep foundation” is a widely used non-destructive test method for the evaluation of pile quality, and integrity. The test can also be used to estimate the unknown length of existing piles and foundations. In the low strain impact integrity testing, the response of the pile to an impact on the head of the pile shaft is determined by a high precision transducer mounted on the pile head. The transducer can either be an accelerator, or a velocity sensor. The test standard allows two different procedures to obtain acceleration and force information: 1) Pulse-Echo Method (PEM) or Sonic-Echo (SE) and 2) The Transient Response or Impulse-Response (IR).

What Information Does Low Strain Pile Integrity Testing Provide?

The low strain pile integrity test results can be used to study the following:

- Changes in the Pile Cross Section (Necking or Bulging)

- Discontinuity in Piles (Voids, major cracks)

- Consistency of Pile Materials (Concrete quality, segregation, honeycombing, soil inclusion)

- Estimate Pile Depth (Note: only possible when the pile toe response is super clear)

Limitations of Low Strain Pile Integrity Testing

The low strain pile testing can provide an indication of soundness of pile materials and integrity; however, the test has certain limitations:

- Low strain pile testing does not provide pile bearing capacity

- The test cannot be used over pile caps.

- This test is not effective in piles with highly variable cross sections

2- Crosshole Sonic Logging

Ultrasonic Crosshole Sonic Logging provides information about the homogeneity and integrity of concrete. The method can be used for quality control of concrete piles. This method overcomes the limitation of low strain impact integrity testing. vertical holes are created using tubes at the time of pile construction (at least two). The tubes are filled with water. An acoustic wave emitter transducer is lowered to the bottom of one tube; while another acoustic wave receiving transducer is placed at the bottom of second tube. Both transducers are pulled upward at the same rate. The signals are analyzed and integrity profile of the pile is developed. an ultrasonic profile. The test procedure is standardized as ASTM D6760

Applications

Cross Hole testing can be used to determine the location of defects, as well as identifying the extent of the defects. The test can be done on larger diameter piles. To learn more about the CSL test, read our next article at “What is Ultrasonic Crosshole Test?”

Limitations

Requires installation of tubes during pile construction. Data recording and analysis might be expensive. Access to the tip of the wall is needed for most applications.

3- Thermal Integrity Profiling

Thermal Integrity Profiling (TIP) uses the temperature variation of cement paste of concrete for integrity evaluation of piles and deep foundations. This method covers a wide range of piles and deep foundations including drilled shafts, bored piles, micro-piles, augured cast-in-place piles, continuous flight augured piles, drilled displacement piles and more. The concept behind this technology is to record temperature changes and history during the curing time of cement. This temperature can be correlated to the strength gain of concrete and integrity of piles and deep foundations. TIP has several advantages compared to previously described methods:

- Thermal Integrity Profiling can be used to evaluate the portion of concrete outside the steel cage.

- Thermal Integrity Profiling provides real-time data on pile quality, which can shorten the construction timeline.

- Data interpretation is relatively easy.

TIP measurement has some limitation for integrity testing of piles and deep foundation including:

- Thermal Integrity Profiling can only be used for integrity testing of new piles.

- Thermal Integrity Profiling requires a reference graph for comparing recorded logs for integrity evaluation.

- TIP wires and sensors may be damaged during installation and concrete placement.

- TIP measurement is a comparative method for integrity evaluation. Change in mix design may result in a huge difference when compared to the reference graph even though the concrete pile is sound.

Stephen Flux

Can you provide a quote for purchase of the equipment

FOLA ADENIYI

Hi.

Your comment on pile integrity test appreciated. We shall be glad to acquire the equipment capable to generate image of the pile in the ground. In addition to the length and diameter along with other information that dictate the integrity of the pile. Kindly furnish us the cost of various brand of pile integrity test equipment available in your company.

Luis Eduardo Galavis

As a Geotechnical engineer consultant I would probably purchase the equipment. Could you please informe me it`s cost.

Luis : Galavis M. MSCE

Reuse of Existing Piles - How NDT Can Help | FPrimeC Solutions

[…] Test Method for Low Strain Impact Integrity Testing of Deep Foundations), generally referred to as Pile Integrity Testing (PIT), is mostly used for concrete piles with access to pile head and top surface. The test results can […]

Non-Destructive Evaluation of Unknown Foundations | FPrimeC Solutions

[…] Pile Integrity Test (PIT) + Bending Waves with Short Kernel + Ultra-Seismic + Surface Wave Spectral Analysis + […]

Reuse of Existing Piles - How NDT Can Help - iPile

[…] Test Method for Low Strain Impact Integrity Testing of Deep Foundations), generally referred to as Pile Integrity Testing (PIT), is mostly used for concrete piles with access to pile head and top surface. The test results can […]

Ali Talafha

what is the maximum pile depth can be handled with this test?

Tiffany Locke

Thanks for explaining how the pile integrity test sends a shock wave that travels the length and will set up secondary reflections to be sent with the return signal if there are any defects or discontinuities. Properly inspecting the piles and other parts of your project would probably be important to ensure that they're stable and in good condition. In order to get the most accurate results and ensure you understand what they mean, it would probably be important to hire a professional company for installation and the other services you require so you can avoid problems.

NC Pandey

How much it cost to undertake test for a pile of 750 mm dia and 40 meter length

Quality Control of Concrete Piles | FPrimeC Solutions

[…] the pile. The acceleration/velocity data are analyzed to identify potential defects in the pile. Pile integrity testing is standardized as ASTM […]

5 Integrity Problems of Concrete Piles | FPrimeC Solutions

[…] Learn More […]

How to Test Concrete Using Impact-Echo Method? | FPrimeC Solutions

[…] Impact-Echo is a nondestructive test method for evaluating concrete and masonry structures. The test utilizes of stress waves (sound) that is normally generated through concrete by an impactor (Impact), are recording the reflections and refraction from internal flaws and other boundaries (Echo). Generally, a pulse is generated by an impact at one single point. The resulting stress wave propagates in all directions. In this regard, the generated wave lacks the directionality of a pulse that is generated by a large transducer (as in the case of ULTRASONIC PULSE VELOCITY). Since the reflections are arriving in all directions, the test method works best in slender element, such as piles where the external boundary guides the wave through the pile. In this particular application, the test has been standardized as low strain pile integrity test. Read more about PILE INTEGRITY TEST. […]

SATISH C DHUPELIA

" PIT ", has been recommended by me for Pile Integrity Tests for most of the Pile Installations, with my recommendations on ALL the Projects as executed, as also those ongoing, with myself being Consulting Structural Engineer.

I would like to know, whether this system, can be deployed, indirectly, for verification of continuity of Concrete Mass, in RCC Columns, post their construction ?

Why and When to Use Concrete Piles? | FPrimeC Solutions

[…] + Low Strain Impact Integrity Testing - Read More + Ultrasonic Cross Hole Testing for piles with accessible tip, + Parallel Seismic (ACI 228.2R) for piles covered up by pile-cap […]

How To Perform Low Strain Pile Integrity Test? | FPrimeC Solutions

[…] Low Strain Pile Integrity Test belongs to the family of shaft head impact tests, where the response of an impact made on the head of pile head is recorded by a motion transducer (i.e. accelerometer), and used for analysis. Alternatively, engineers can use other tests such as crosshole or down-hole tests for the purpose of integrity test. […]

Wallace

Your post on pile integrity test is completely appreciated. I really enjoyed reading your post, keep it up!

Chance Cook

In my opinion, non-destructive testing methods are always the best way to go. There is no need to ruin something just so you can test it. That sounds counter-productive to me and a total waste of everyone's time if you can do it without damaging anything.

Salsu Sabiu Kibiya

i really appreciate the way that you explained more about pile integrity test(PIT)