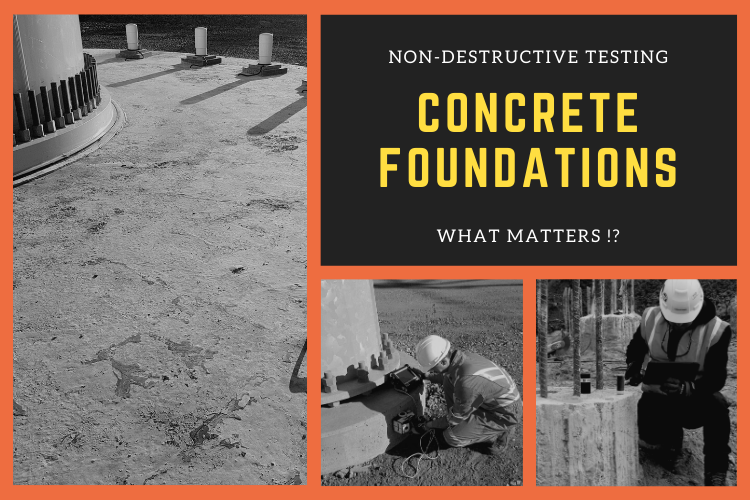

This article presents a brief review on Non-Destructive Testing of Concrete Foundations. It also discusses how engineers can utilize NDT to assess defects such as cracking and voids, and the deterioration mechanisms such as alkali-silica reactions, and corrosion of steel reinforcement.

Concrete foundations are a key component in every major structure. They provide the much-needed stability to structural systems, and/or heavy industrial equipment they are supporting. The foundation system and type depend heavily on the superstructure load, and soil properties. As a result, concrete foundations may appear in different shapes, and sizes. In general, foundations can be grouped as:

- Shallow foundations

- Deep foundations

In reality, engineers might face a broad spectrum of shapes, configurations, and structural detailing. This makes the inspection and assessment of foundations particularly challenging.

Non-destructive Testing of Concrete Foundations

Non-destructive testing solutions have long been used to assess structural systems; several NDT methods have been developed for the quality control and evaluation of deep foundations and piles over the past decades. Most of these methods have been adapted in standards and codes; however, in the case of specialty foundations, engineers may need alternative solutions to assess the integrity, durability and structural performance.

Specialty foundations might have unusual cross-sectional details, with design/detailing requirements that make their inspection challenging. Understanding structural details help design a reliable testing solution that can help collect key information about the condition of the foundation element.

Deep Foundations and Piles

Deep Foundations, Piles and drilled shafts are an important category of foundations. Despite their relatively high cost, they become necessary when we want to transfer the loads of a a heavy superstructure to the lower layers of soil. Another reason for choosing a pile foundation is the condition and quality of soil layers. Piles and deep foundations are commonly used to provide stability in Bridge structures, High-rise buildings, Industrial oil/gas facilities, Transmission lines, and Telecommunication Towers.

Application of non-destructive testing for deep foundations has a long history. Various techniques have been developed over the last 60 years, and have been used by engineers around the globe. NDT methods can either be used in the quality control and quality assurance process, or in the assessment of existing foundations. The following describes some of the most widely used NDT methods for evaluation of deep foundations and piles:

- Low strain pile integrity test

- High strain pile integrity test

- Cross-hole sonic logging

- Impulse-response method

- Parallel seismic method

The main advantage of these testing solutions is that they are cost-effective, and, when performed properly, can identify hidden defects inside pile elements.

Wind Turbine Foundations

Wind Turbines are often supported on massive concrete foundations: These foundations can be as large as 10-15 meters in diameter, and as thick as 2 to 3 meters, depending on the size of the turbine, the shaft, and soil characteristics. This can lead into buildup of significant heat (from the cement hydration process) and develop massive temperature gradient in the foundation block. This may result in thermal contraction cracking shortly after the concrete hardens — compromising the structural integrity and durability of the foundation.

Several NDT methods can be used to evaluate the quality of concrete in these mass concrete components:

- Temperature and Maturity Monitoring: Read More

- Ultrasonic Tomography

- Impact-Echo: Read More

- Ground Penetrating Radar

A combination of these techniques help engineers collect critical information about structural details (as in the case of detecting rebar spacing in an existing foundation), as well as internal anomalies, such as void or discontinuities. Learn More

Foundation of (Gas/Steam) Turbines and Generators

Turbine foundations are massive concrete blocks that provide the much needed stability for the shaky starts of the engines (gas combustion, and the rotary parts). Depending on the size of the generator, the size of the foundation can change. However, in general, these are big blocks of concrete with steel reinforcement in the exterior faces. Since the thickness of these elements are large, ultrasonic methods such as ultrasonic tomography would be of limited use.

Instead, customized solutions such as seismic tomography can be used to study the quality and integrity of concrete in 2D and 3D. In this method, a source of energy, such as sledge hammer is used to perpetuate the concrete on one side, while receiving transducers collect the arriving signal across the foundation element. The test results are then analyzed to create scans of potential defects inside the concrete element.