Corrosion inspection of structural anchor bolts can be quite challenging. The reason is that access to these buried elements is often very difficult. The visible part of the bolt is usually in poor quality, and mechanical tests such as pull-out is not an option. Non-destructive ultrasonic testing of anchor bolts provide a very good method for testing the state of corrosion.

Structural Anchors

Structural anchors are widely used in variety of civil engineering projects, including:

+ Buildings: it is used to install steel columns to the based plat and concrete foundation

+ Oil and Gas industry: It is used to anchor stream lines, vessels, rotating and reciprocating equipment onto supporting foundations

+ Geotechnics: It is used to stabilize the slops in tunnels and to reinforce excavation walls

Anchor bolts are used to fasten superstructure to concrete foundation. In geotechnical engineering projects, they are used to prevent stabilize the excavations and tunnels. The length of anchor bolts varies from some centimeters to several meters, depending on the application.

Condition Assessment of Structural Anchor Bolts

The condition of anchor bolts may remain unknown, because they are embedded within the concrete foundation. However, over time, corrosion can initiate and propagate along the anchor. This will result in loss of effective cross sectional area, and eventually lower strength. The corrosion of anchor surface will also result in a poor bond between the anchor and the concrete, which will affect the strength of the bolts. Corrosion can ultimately result in major cracks along the anchor.

The progressive nature of corrosion reaction, when combined with structural loads (i.e. dynamic loads, vibrating machinery, etc) can result in catastrophic events. Therefore, regular inspection and assessment of these bolts is necessary.

Engineers use a combination of telltale signs (visual inspection) and mechanical tests (i.e., pull out test) to understate about the present state of anchor bolts. Rust staining, increase in vibratory movement, misalignment of equipment, extraordinary displacement are some of telltale signs that are generally used in order to evaluate the present state of anchor bolts. However, most of anomalies in anchor bolts remain hidden until a disaster (such as earthquake or any other significant overloading) occurs.

Non-Destructive Ultrasonic Testing of Anchor Bolts

Nondestructive Testing (NDT) can effectively be used for corrosion inspection and structural evaluation of embedded anchor bolts. These methods are rapid, easy to perform, and minimally intrusive. In addition, Ultrasonid testing of anchor bolts can detect potential damage mechanisms at the early age, (much earlier than the time when the visual signs are appeared in the structure.

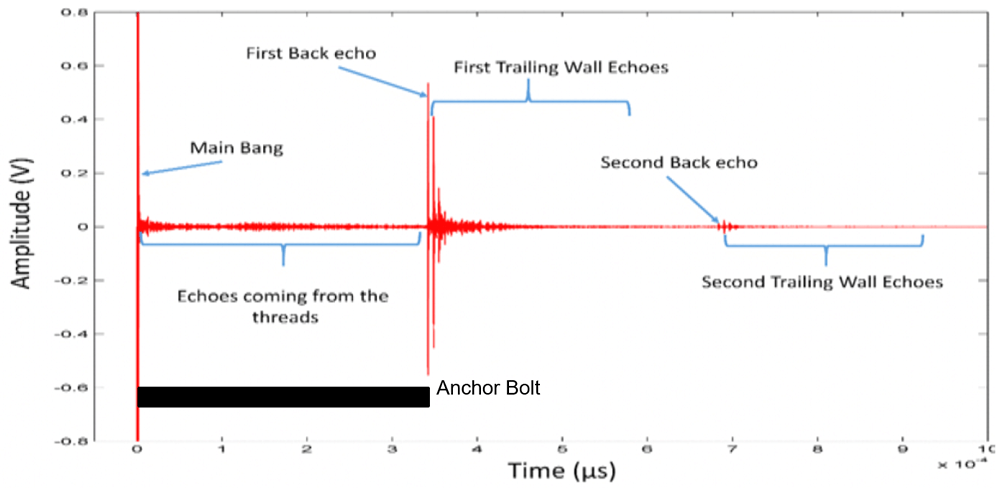

Ultrasonic pulse-echo is one effective way of evaluating the condition of these anchors. In this method, the transmitter and receiver (normally a one piece transducer) is placed at the tip of the anchor bolt. In this context, pulse-echo requires very small access surface, which makes it ideal for testing anchor bolts. Ultrasonic pulse is then applied to the tip of the anchor bolt. The pulse travels along the length of the anchor (a specified range of frequency is used for practical considerations). The wave is reflected from the other end of the anchor, or any anomalies (including cracks and discontinuities) along the anchor length. The reflected pulse is received by transducer at the tip of the anchor. The time difference between the arriving reflections is used to locate the anomalies.

A time-domain along with a frequency-domain analysis is applied to detect anomalies and deficiencies (such as corrosion defects, cracks); and to find out about the average cross section decreased due to corrosion.

Osama

Can I learn more about how to estimate the exact position of the crack or damage in the anchor related with the time of the traveling wave, is there any particular formula for that?

Best regards ..

B Pradeep Reddy

Can you perform the UT on M100 anchor bolts with 3m length?

Anonymous

Same question. M100 and M80 bolts upto 3m length with threaded length upto 400mm and pitch 6mm.

Gustavo Goncalves

Good afternoon Ladies and Gentleman,

We are currently facing a real case where our global client anchor bolts are extremely corroded, and in need of some sort of Nondestructive Testing (NDT) to check its integrity, before any other actions/services.

We are quite interested in your Non-Destructive Ultrasonic Testing solution and would appreciate if we could receive any additional technical input about it.

Anchor Bolts in question are 3.650 mm long, with diameter 36 mm, hot dip galvanized steel

Would you also let us know how to compare the Ultrasonic Testing to a Reflectometric Impulse Measurement Technology (RIMT) testing, actually asked by our client?

Looking forward to hearing from your side.

Best regards,

Angela Waterford

It's true that over time, anchor bolts will deteriorate because of corrosion that can propagate in those structures. I'm guessing that this is the reason why people conduct phased array ultrasonic examinations on them. Knowing the status of a building or a certain structure has always been on my mind since I've been curious as to how they are assessed, so maybe I should know more about this and see if this can be conducted on the building I inherited from my father.

awma

Can anyone know limitation for anchor bolts corrosion