Taking core samples from concrete structures is required for comprehensive assessment of durability and structural performance of the structure. The compression test on core samples is known as the most reliable method for assessing the compressive strength and a means of quality control. The procedure for taking core samples and testing them has been standardized (ASTM C 42, and ACI 318). However, with all the benefits coring brings to the table, coring has certain disadvantages. In addition, the selection of core locations in structure can be a challenging task. In this article, we will review the benefits and disadvantages of taking cores. We will also discuss how non-destructive testing has changed the paradigm in recent years.

Concrete Coring | Challenges

Coring in concrete structures come with certain challenges. To make coring more efficient, one needs to address the following challenges:

1- How many cores are needed? ,and where?

The quantity and the location of cores should be selected such that they represent the strength distribution within the member. The cores should also be a realistic representation of concrete quality. It is safe to say that increasing the number of cores can deliver a more realistic distribution of strength, but at the same time, leave more weak points in concrete.

The type of condition assessment also plays a key role in selecting the location of cores.

1- Likely strength/stress: when the objective of an assessment is to evaluate the structure under service loads, the cores should be taken from areas where the minimum strength and maximum stress coincide (i.e. mid-span for the beams, or any face near the top of lifts for vertical elements).

2- Highly reinforced or slender members: when the element is highly reinforced, or coring can significantly affect the integrity or structural performance, the cores should be taken from nearest non-critical section

3- Aesthetic consideration: concrete coring can leave unpleasant scenes on the structure. The location of cores can be adjusted to reduce the impact on aesthetic features.

4- Durability concerns: when durability of concrete (i.e. permeability, protection against radiation), the number of cores should be very limited.

Concrete Coring | Benefits

Taking core samples provides invaluable information about an existing structure. Coring can also be used as a means of quality control when things go wrong with concrete material quality or the pouring and curing process. The following information can be obtained with further assessment of cores:

1- Compressive strength: Perhaps, measurement of compressive strength is the primary objective in most cases. Concrete cores can provide precise information about the strength of concrete.

2- Density: Cores can be used to determine the density of concrete.

3- Water absorption: concrete cores can be tested to evaluate the water absorption of concrete. Water absorption can provide basic information about the porosity, and inter-connectivity of pores.

4- Bulk Electrical Resistivity: Bulk electrical resistivity of concrete can be determined by testing concrete core samples. ER provides valuable information about the resistance of concrete against penetration of chloride ion into concrete.

5- Visual assessment of cores: Cores, and the drilled hole can be used to evaluate the visual condition of concrete defects, such as cracks, voids, and honeycombing.

Concrete Coring | Disadvantages

Taking cores from concrete elements have certain disadvantages, including:

1- Weak points: taking cores leave weak points within the element. The location of cores is normally repaired by standard or high strength patch repair materials. While repair materials often have adequate strength, the weak points can affect the integrity of structure, and durability performance.

2- Intervention: taking cores can damage structural performance of the element, especially if the coring damages the existing rebar. Cutting rebar in an already distressed structure is the last thing an engineer wants in the field.

3- Subjective test: The selection of core locations can be very subjective. After all, the very nature of tests means that the engineer or the technician may need to compromise between the number of cores, safety of the structure, and intervention to the structure.

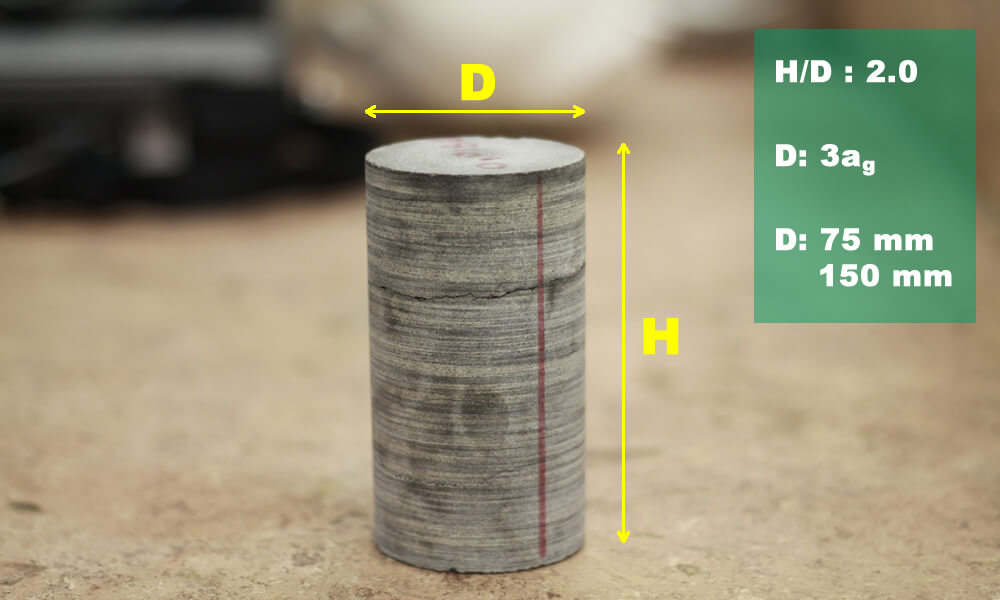

Concrete Cores | Dimensions

Size

When the purpose of coring is to evaluate the compressive strength of concrete, the minimum diameter of concrete core should be at least three (3) times the nominal maximum aggregate size. Different codes and standards set different values for the minimum diameter of concrete cores, ranging from 75 mm (in Australia) to ideal 150 mm (Britain). However, 100 mm core is a practical size in most structure inspections. The accuracy of cores for strength reduces when the ratio of diameter to nominal maximum aggregate size decreases.

Height to Diameter ratio (H/D)

Most standards refer to H/D of 2.0 as the standard ratio for structural cores. However, obtaining cores that meet this specification is not always practical. For example, in thin slabs (6” = 150 mm), it is very hard to obtain a core with this ideal aspect ratio. Correction factors have been used to correct the strength values for cores that do not have the preferred H/D of 2.0. The accuracy of the correction factors decreases as the H/D decreases.

Non-destructive testing | A new paradigm

Recent developments in the NDT methods can be used to improve the process of coring in concrete, such as location of cores, number of cores, and interpretation of results.

Ground Penetrating Radar (GPR): This method can be used to determine the as-built layout of steel rebar within concrete. The as-built layout of steel rebar can be used during the course for drilling cores in order to avoid from cutting steel rebar.

Combined Methods (UPV+ RN): NDT methods can be utilized to optimize the number of cores and core positions. To do so, it is recommended to combined NDT methods such as Ultrasonic Pulse Velocity (UPV) and Rebound Number (Schmidt hammer). The results obtained from these NDT methods can be used to evaluate the compressive strength of concrete. Based on these methods, maps of compressive strength can be developed to study the strength variation over concrete members. This map can be used to determine the number and location of cores. The combination of these two methods can cover the deficiency of each individual test, and improve the accuracy of strength prediction.

Eric Carleton, P.E.

Thank you for this article. Another benefit a core will provide is visual inspection of reinforcement placement and consolidation of the mix in this area should some reinforcing steel be encountered. Additionally, I have heard arguments and seen data both ways that the inclusion of steel within the core sample detrimentally affects the compressive strength testing. With respect to this I believe the technician / engineer needs to make a judgement on the amount of steel within the sample observe for any small voids around the steel, etc. that could skew the testing. If this is so, then the steel component could be sawed out of the sample and the test result would utilize the correction factor as needed.

Jerry

Great article, I did not know that coring can asses the bulk electrical resistivity of concrete. Good point about not cutting into rebar as that is a big no-no.

Ivan Perozo Padilla

Grateful for the information you have expressed, I would like to express my professional experience on the subject. Since the beginning of the eighties we have made in Venezuela the structural evaluation of buildings, necessary for example for changes of use, seismic resistant verification, etc. There is one aspect that does not mention which is the statistical evaluation of the resistance on site, it is not necessary to take core drills in critical areas, for that is used the statistical correlation of the resistance on site of few cores with the speeds of the ultrasonic pulse, this correlation allows us to extrapolate to determine, with a much higher population of speed data, the compressive strength of the concrete in situ to a large portion of the structure without damaging it with an exaggerated number of cores and with a confidence also calculated statistically.

David L. Johnson, P.E.

The article is pretty good. However, it should have been proofed. There are misspelled words and sentence fragments. The author also left a few things out.

Rebound number testing applies to the surface of concrete and does not give an indication of the internal strength of the concrete. In addition, compressive strength corresponding to rebound numbers measured by a specific hammer are based on testing of standard 2" cubes. Rebound hammers should be correlated/calibrated to actual concrete for a project (i.e. cores). Rebound number testing should never be used as the sole basis for the acceptance of concrete compressive strength.

Penetration testing of concrete is another method of evaluating the strength of concrete. However, it too gives an indication of the strength of concrete at the surface.

UPV can be useful however it does have one significant disadvantage. The presence of reinforcing steel can affect the pulse velocities measured lwhich can ead to an inaccurate estimation of concrete strength. I do agree that GPR be utilized to map existing reinforcing steel to assist with selecting UPV test paths of concrete. With respect to strength prediction using UPV, the engineer must understand that test results provide an overall indicating of concrete quality and not an accurate prediction of concrete strength.

Creating weak spots in structural members is not the ideal method of evaluating existing structures, it is by far still the best way to get consistent, confident results.

Dr Farhad Nabavi, PhD, CPEng, IntPE

Dear David L. Johnson,

UPV testing Accuracy:

Based on the vast studies, published papers, and case studies, the existence of steel reinforcement has approximately between 1% and 1.5% effect on the compressive strength compared to the concrete without reinforcing steel both measured by UPV testing. Therefore, it does not have a great influence on the results. This effect is negligible.

As an average of all test results, UPV testing shows between 4% to 5% error in measuring the compressive strength compared to the extracted core compressive strength. On the other hand, if the average of compressive strength of some extracted cores is 40 MPa, the UPV testing will show the compressive strength 40 +(-) 1.8 MPa which is quite acceptable results for the assessment of an existing structure.

Common Defects in Bridge Structures | FPrimeC Solutions

[…] The condition survey of bridge structures often involve a series of destructive tests (sawing, cutting, taking core samples). Core samples are used to study the visual condition of the core profile (showing sign of cracks, corrosion, delamination), and testing them for compressive strength, and chloride content. The main advantage of these methods is their compliance with most codes and guidelines; however, one should note that the coring increases the chance of damaging an already damaged structure. Overall, destructive test methods are not particularly ideal for identifying the location and extent of defects in bridge structures over large areas (such as large bridge decks). To learn more about the challenges of these methods, read MAIN CHALLENGES OF CONCRETE CORING […]

How to Evaluate Bridge Abutments? | FPrimeC Solutions

[…] Challenges of Concrete Coring -- READ MORE […]

Richie Doherty

If your space requires a focus on exceptional cable management, rather than coring and drilling, check out https://freeaxez.com/ for a low-profile adaptive access floor solution.

Natalie

Thanks for the article. Stumbled on this article while researching about core drilling techniques. I should add a section about entailing challenges as well. Will ensure to cite this article.

Thanks again

Thomas Jameson

It's good to know that cores can be used to determine the density of concrete when drilling. My brother needs to get some concrete drilling done, but he doesn't know how dense his concrete is. I'll pass this information along to him so that he can check the density of his concrete.

Non-Destructive Testing for Detailed Bridge Condition Survey | FPrimeC Solutions

[…] Concrete cores are often extracted to study the mechanical and durability properties of concrete. Cores can be tested to provide information about the compressive strength. They can also be tested for chloride content and air content. While the total number of concrete cores can be quite significant for larger bridge decks, a few of these cores are further studied for strength or chloride content. Some of the most common challenges of concrete coring is summarized here. […]

5 Methods for On-Site Evaluation of Concrete Strength | FPrimeC Solutions

[…] concrete samples (Read More: Challenges of Concrete Coring) and testing for compressive strength is often considered the most cost-effective and most reliable […]

Greta James

Yesterday, I was talking to my sister, and she mentioned that they have run into a snag on their home renovation. They are not sure if part of the cement is structurally sound. Thank you for pointing out that a core test can help determine the strength of the concrete! I will have to tell my sister that they should look for concrete cutting services to help them.

Taylor Hicken

It's interesting to know that the strength distribution depends on the quantity and the location of cores to be located. The higher the number of the cores, the better the strength distribution. I would like to think if a company needs to work on a project, they should hire a core drilling service that can provide the best quality cores.

Adam Golightly

I can understand how a business could really benefit from having the right drilling in order to be more effective. It could be really useful to have the core drilled by a professional in order to be more efficient. It was interesting to learn about how they can test concrete core samples in order to determine the bulk electrical resistivity.

Adam Golightly

I can imagine that a business could really benefit from getting the right drilling for the foundation of their project. Making sure that they can get it done by a professional could allow them to be more productive. I liked what you said about how a building's durability and structural performance can be determined with core samples.

Core Drilling Brisbane

Great article. I especially liked the section about the type of condition assessment when selecting the location of cores.

Guy Davidson

Very nice post. I just stumbled upon your blog and wanted to say that I have really enjoyed reading your blog posts. Anyway, I'll be subscribing to your feed and I hope you post again soon. Big thanks for the useful info.

FPrimeC

Thank you for your comment and looking forward

Toni Peters

Thanks for sharing your great idea! Very informative and lighthearted and fun at the same time. Very nice!

Linda

This article shows the core samples taken last year from the collapsed Surfside condo: https://www.miamiherald.com/news/local/community/miami-dade/miami-beach/article252511773.html

Is that rebar cut in both cores? The pictures seem to show a cut rebar in the samples. This statement from your article is haunting: "Cutting rebar in an already distressed structure is the last thing an engineer wants in the field."

Non-destructive Evaluation of Concrete in Mine Facilities - FPrimeC Solutions Inc.

[…] Extracting concrete cores to assess the compressive strength has several challenges: […]