Introduction

The tragic collapse of the 12-Storey Beachfront Condo in Florida has reignited discussion around proper inspection and maintenance of buildings in North America. At the moment there is limited information available about the condition of the Florida building prior to its collapse with the inspection report by Morabito Consultants being one of the only reports to provide any insight. It will take some time for structural forensic experts to accurately identify the potential causes. In this article we will review some of the most common challenges that face structures like the Surfside condominium in Florida and ways in which we might prevent another building collapse.

Why Buildings Collapse?

Deterioration of Concrete Structures

The Deterioration of construction materials over time is inevitable and is arguably the first step in understanding why a building might collapse. Steel bars in concrete elements that are exposed to chloride or saline environments — like slabs and columns found in parking garages for example —corrode over time.

Steel corrosion is a common deterioration mechanism in reinforced concrete buildings and parking garages.

Concrete materials containing active silica can experience extensive cracking due to a phenomenon called Alkali-Silica Reactions (ASR) in which alkalis from the cement reacts with the active silica in the aggregates, resulting in a gel that swells when exposed to water and increases internal pressure. Concrete subjected to aggressive chemicals like de-icing salts and contaminated soil can experience disintegration. The deterioration of construction materials is the most obvious reason for building collapses, but there are additional challenges that contribute to a building’s downfall.

Read More: Deterioration of Concrete Structures

Complexities

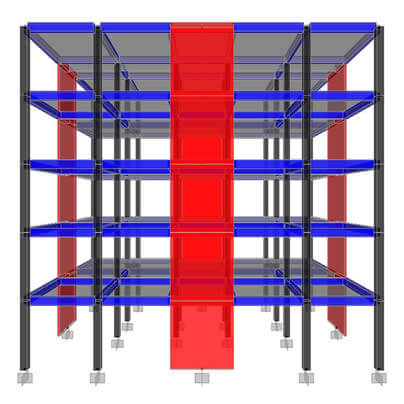

Structural systems are a complex matrix of foundations, columns, beams, floors, and lateral load bearing systems to brace against wind and earthquake loads. While each of these components has their own complexities in design and detailing requirements based on demand load, it’s the combination of these elements together that makes things even more challenging. Understanding the load paths — how the load is distributed among adjacent components when a column or beam fails and estimating forces in each — is an easy task at the design stage but evaluating them for an existing structure can be extremely challenging with so many unknowns and uncertainties to account for.

Limits to structure inspection guidelines are a challenge as well. Here in Canada, our inspection and maintenance protocols for key infrastructure facilities like bridges are well-developed. Inspection guidelines like the Ontario Structure Inspection manual (OSIM) for bridge structures, for example, require that every bridge longer than 3 meters should be visually inspected (close-up) every two years. For residential buildings and high-rise condominiums, however, the guidelines are not crystal clear. While the Structural Condition Assessment of Existing Buildings and Designated Structures Guideline by the Professional Engineers Ontario (PEO) is a great resource to help engineers perform better assessments. The guideline doesn’t clearly specify the frequency and extent of inspection and assessments, leaving gaps in how, and when, owners and maintenance managers take action.

Limited Inspection and Maintenance Budgets

In talking to asset owners — whether capital, residential or commercial assets — you’ll often hear that “there is not enough money right now” for inspections. Many asset owners focus their budget on day to day needs such as hot water, heat, HVAC, proper lighting, and electricity rather than on structure inspection and proper maintenance with many asset owners feeling that money invested in inspection is lost capital. While major asset owners in oil, energy, nuclear and transportation have implemented much better inspection protocols, the residential and commercial sector still lacks universal understanding of the structure inspection needs. Truthfully, there will always be a lack of budget and yes, quality inspections and assessments can be costly, but ignoring minor issues as a structure ages can result in something serious and threaten lives. And, as engineers all learn from the code of ethics, public welfare is paramount. Nothing should be more expensive than the lives and wellbeing of residents.

Element Level Inspection vs Holistic Approach

As engineers, most of our inspections and testing tasks are requested and planned at the “component level” meaning the beams, columns, floors, or walls (i.e. we need inspection in one or two certain areas). While this type of inspection is quite useful in evaluating particular maintenance needs, it often fails to provide insight into the structural response of the entire system. For example, a crack in a beam in a basement might be considered normal wear and tear, but when it propagates throughout multiple beams and slabs it can be a red flag for structural instability. That said it’s important to develop a holistic approach for inspections that goes beyond providing insight into the quality and structural integrity of the component. Structural engineers need to also solve the jigsaw puzzle of contributing factors — identifying the source and reason(s) behind deterioration — and incorporate them into their numerical models as well as re-assess the structural performance and load bearing capacity of that structure.

Can Building Collapse Be Prevented?

It is very important to note that with the developments of design and evaluation codes and guidelines over the past few decades, building collapse is not so common.

The redundancies in the structural systems provide great defense mechanism against many failure mechanisms. For example, incorporating integrity bars can prevent punching shear and can control progressive collapse to a great extent.

Routine Inspection

The first, and perhaps most obvious, is proper maintenance program that involves routine inspection of structural components.

Condition Assessment

If irregularities are found during the inspection process, detailed assessment might be needed. A comprehensive assessment has four key elements: Adapting a systematic approach using relevant codes, guidelines, standards and more; Using scientific methods and closely observing and collecting data from each crack or leak for insight into the mechanical and durability performance of the structural components.

Multi-Technology Approach

Taking a multi-technology approach to building assessments is also key. Recent advancements in technologies for inspection and materials testing are enabling engineers to collect far better insight about the structural integrity and quality of materials and, for engineers involved in the assessment and evaluation of structural systems, implementing these technologies in their day-to-day practice is key.

There are inexpensive, non-destructive testing devices like a rebound hammer, ultrasonic testing, ground penetrating radar and an impact-echo test that are now capable of identifying subsurface anomalies, help estimate the location and extent of defects, and get a better picture of the condition of elements.

Ultrasonic testing of concrete or welds (in case of steel structures), similar to medical ultrasounds, for instance can identify some of the sub-surface defects that can’t be identified by eye. Pile Integrity Tests can be used to evaluate the structural integrity of concrete foundations while methods like Impact-Echo can be used to evaluate defects like delamination. Ground Penetrating Radar (GPR) can be used by inspectors to accurately identify the location of steel bars and verify conformity of their spacing against the most recent building codes. These technologies and devices greatly improve an engineer’s ability to assess the material properties, determine structural detail and assess the integrity and strength of materials.

Read More: NDT for Structural Condition Assessment

Modeling and Structural Evaluation

In addition to the use of technology, numerical modelling and structural evaluation are critical when significant defects are observed during a structure inspection. Numerical modelling of a structure captures the key features of structural and non-structural components in addition to existing weight of concrete beams and slabs and ‘live loads’ like residents and appliances. It’s extremely important to use the results obtained from intrusive and non-intrusive tests in numerical models to evaluate the residual load bearing capacity of components, as well as the entire structural system. As structural engineers, we need to collect this information, reproduce structural models that are accurate representations of the current condition of the elements, and assess the structural performance like demand versus capacity. Engineers need to work closely with asset owners to identify performance goals — how long they plan to preserve their asset for example —and design remedy/rehabilitation plans to ensure safe and reliable operation of the asset for the given service life.

Concluding Remarks

It truly takes a village to ensure public safety and longer service life of structures. Preventing the collapse of a building doesn’t fall on the shoulders of just one party, but several. Governing bodies need to have clearer guidelines with regards to the inspection of residential buildings, high-rise condominiums and parking garages. Building owners and facility managers must do better in terms of making structural defects a priority and hiring qualified engineers to make inspections and evaluations on a routine basis. And we, as engineers, need to adopt the new technologies and non-destructive testing solutions that are available to us to better evaluate the condition of structures and to properly identify defects in advance.

With everyone doing their part and all these systems in place, more cost-effective maintenance and repair can ensure public safety and help to prevent future devastations.

Taylor Hicken

I appreciated it when you shared that it is best to work with a reliable structural engineering firm that has adopted the new technologies and non-destructive testing solutions. In this way, they can ensure that the structure will not collapse easily. I would like to think if a company needs to work on a project, it should consider hiring a reliable structural engineering service that is experienced and reputable.